Let’s talk about which bandsaw blade to cut angle iron you need. What is angle iron? And why would you need to cut it? Angle iron is a construction material made of iron for joining infrastructure at an L shaped angle. It’s often used in construction for joining structural steel parts.

So, what bandsaw blade to cut angle iron do you really need? At SawBlade we recommend the Bi-alfa Cobalt M42. The Bi-alfa cobalt bandsaw blade has HSS-M42 cutting tips and high wear resistance which result in hard and evenly distributed carbides in the tooth tips.

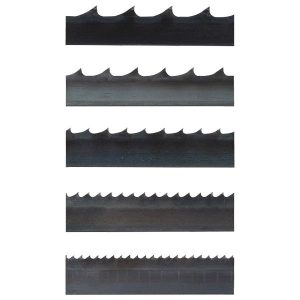

The ideal TPI for this blade is a variable pitch TPI. This is to reduce vibration when cutting. Variable pitch TPI means the teeth change inch per inch (for example: 6 teeth on 1 inch of the blade and 10 on the other). For cutting angle iron, opt for a variable TPI of 6 and 10 or 8 and 12. Our biggest tip when it comes to cutting angle iron, cut slow and let the blade do the work. Another great tip: coolant. Coolant will be your best friend. It’s the key to keeping your bandsaw blade running smoothly.

A great reason for purchasing your Bi-alfa Cobalt M42 through SawBlade is we can customise the blade to fit your machine perfectly. No more mishaps with buying the wrong blade! Once you place you order your blade is manufactured within 24 hours and then dispatched on it’s way to you. Backed with premium quality blades from around the globe and top notch customer service we take pride in our products.

Shipping Australia Wide

Shipping Australia Wide