Bi-alfa Cobalt M42

Bi-alfa Cobalt M42

Constructed from a high speed strip (HSS) and electron-beam welded to a high-strength spring steel alloy backing material, the blade delivers sheer cutting excellence.

This generates the cutting performance of high-speed steel with the extreme toughness and fatigue resistance of an alloy backing steel.

Why use Bi-alfa cobalt M42 bandsaw blades?

- Significantly faster cutting rates for accelerated productivity

- Exceptional performance with cleaner, smoother cuts

- Patented design reduces tooth strippage and machine downtime

- Excellent heat & wear resistance allowing you to cut for longer and harder

- Increased blade life for reduced production costs and blade spend

- Minimal noise and vibration for improved health and safety

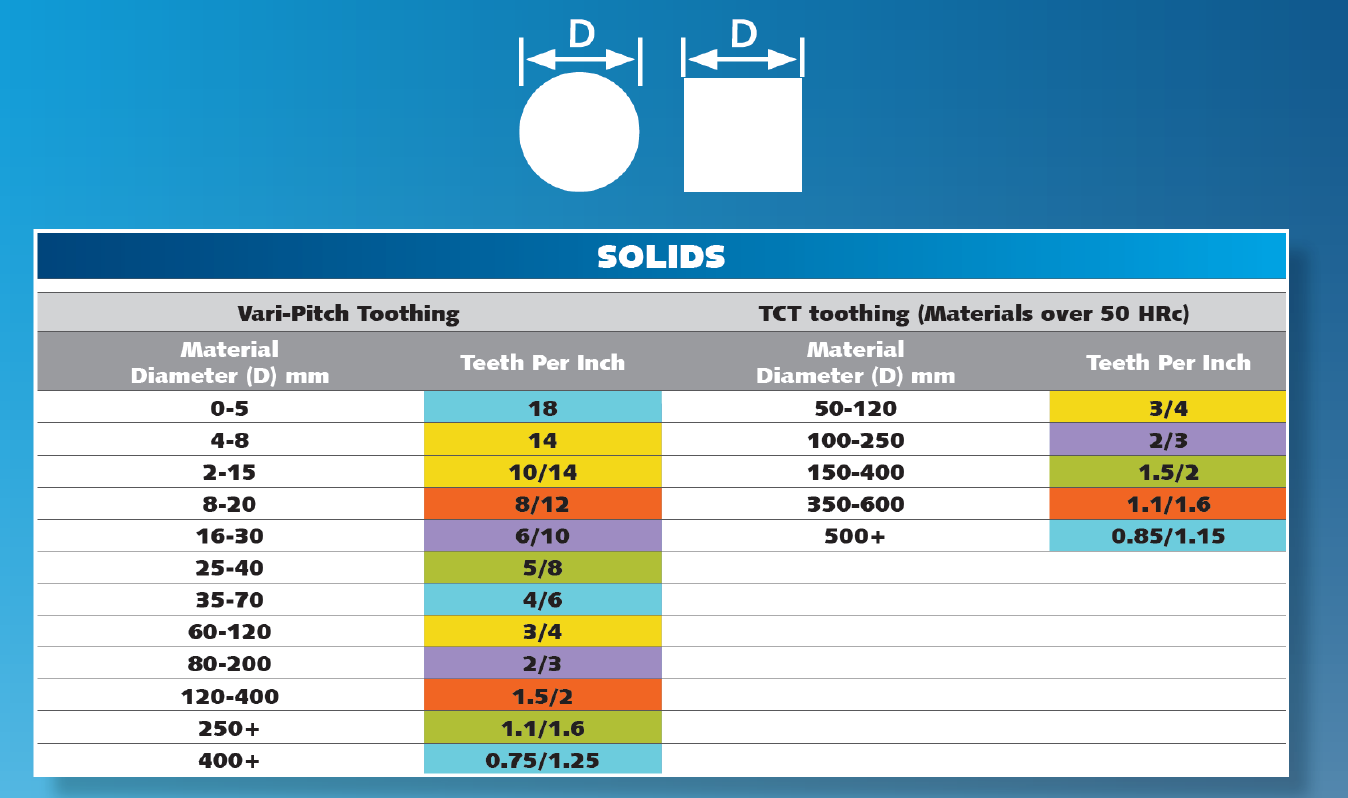

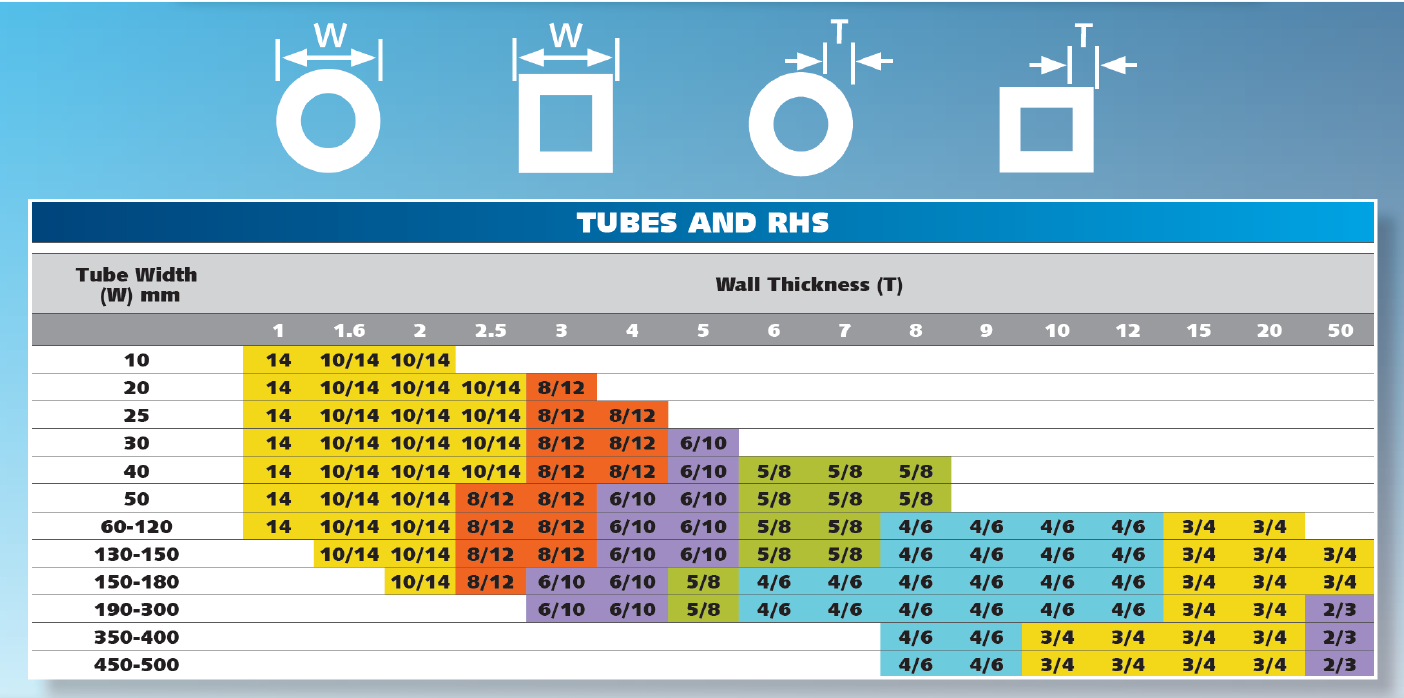

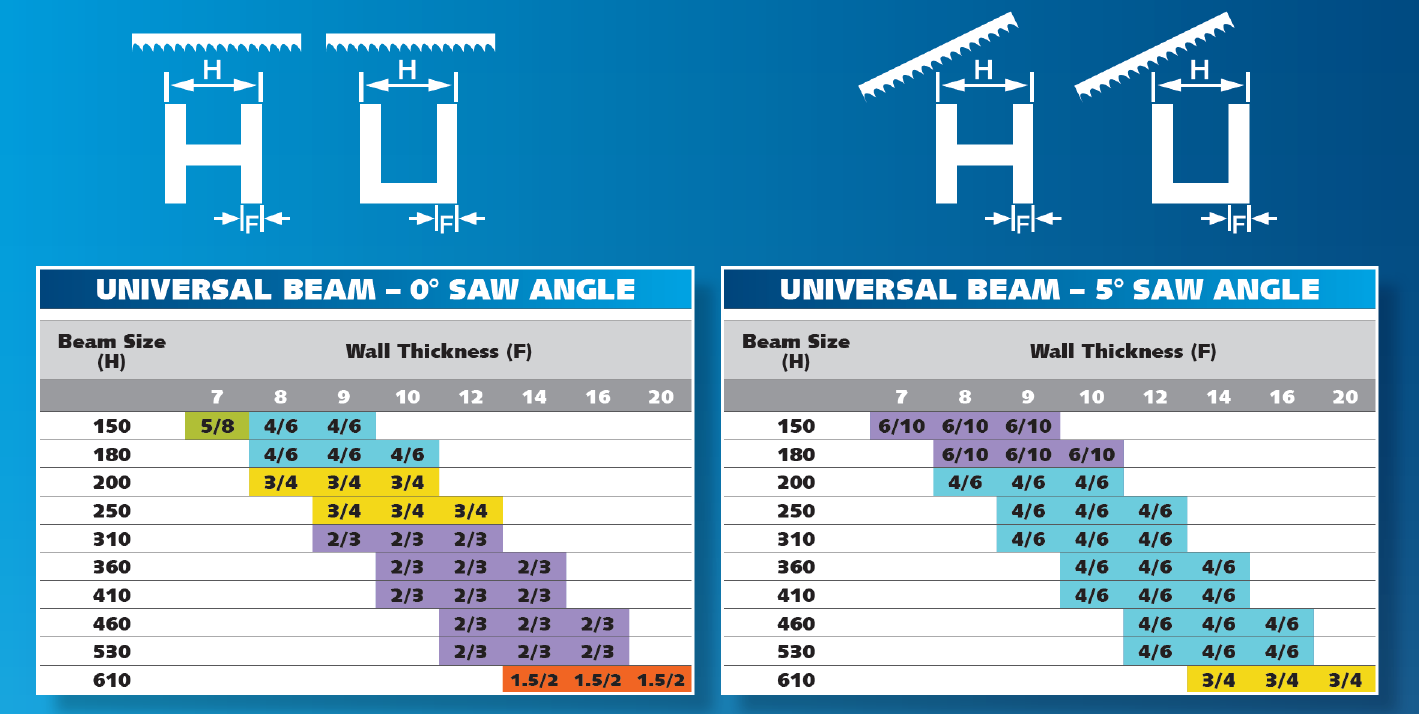

What does the Blade Cut?

Bi-alfa Cobalt M42

5 out of 5 stars (based on 9 reviews)

The Bi-alfa cobalt M42 bandsaw blade is a high-speed steel metal-cutting blade. It benefits from excellent resistance to heat and wear thanks to its bimetal construction.

- Designed for cutting steel up to 44 HRc

- Band widths from 6mm-80mm

- Excellent general purpose blade

Also suitable on:

- Wood (Hardwoods & Softwoods)

- Non-Ferrous metals (Aluminium, Copper & Brass)

-

Free Shipping

over $350 Australia wide

Free Shipping

over $350 Australia wide

-

Manufactured

Manufactured

in Australia Purchase Direct -

100% Safety

Only Secure Payments

100% Safety

Only Secure Payments

-

Australia Wide Shipping Only

LIVE: Orders Placed Today

Australia Wide Shipping Only

LIVE: Orders Placed Today

Talk to our Blade Expert

Get in Touch!

Request a Blade Specialist to give you a Call

Technical Specifications

| Item | Bi-alfa Cobalt M42 |

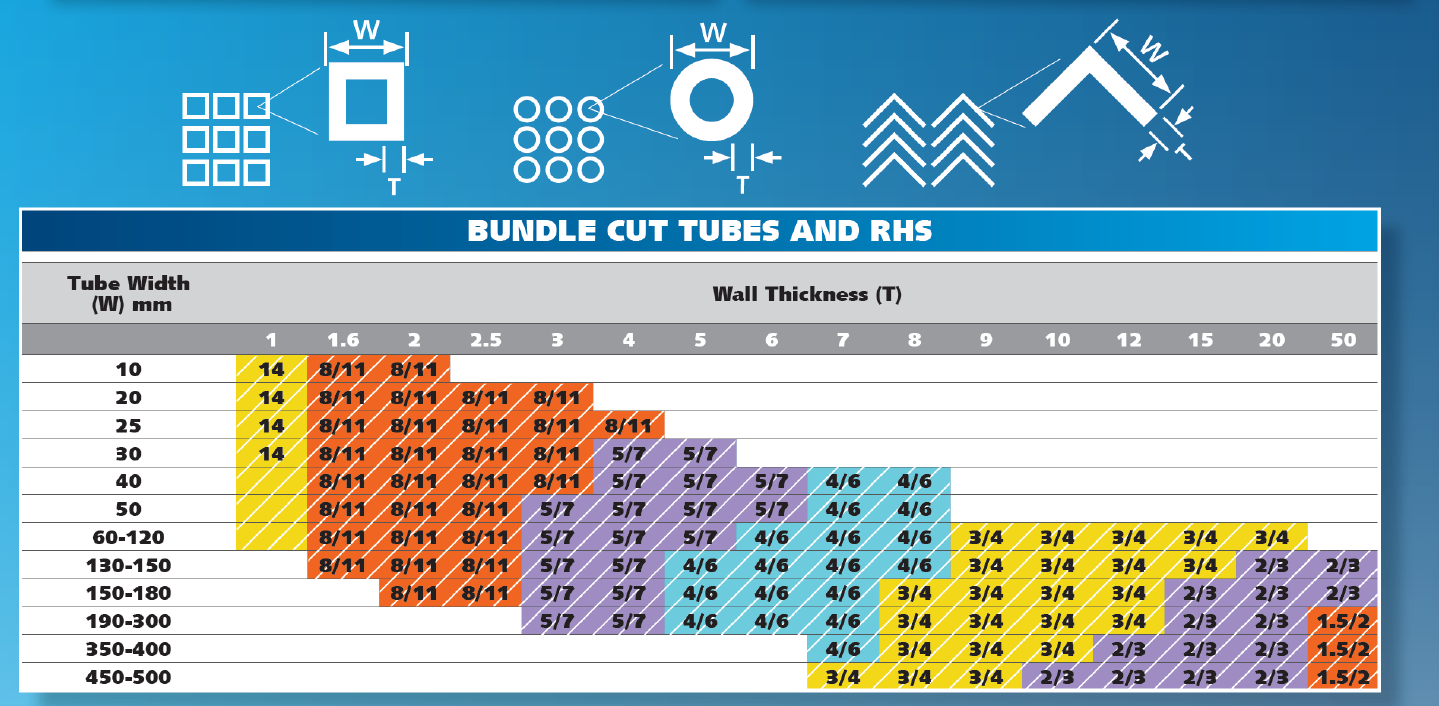

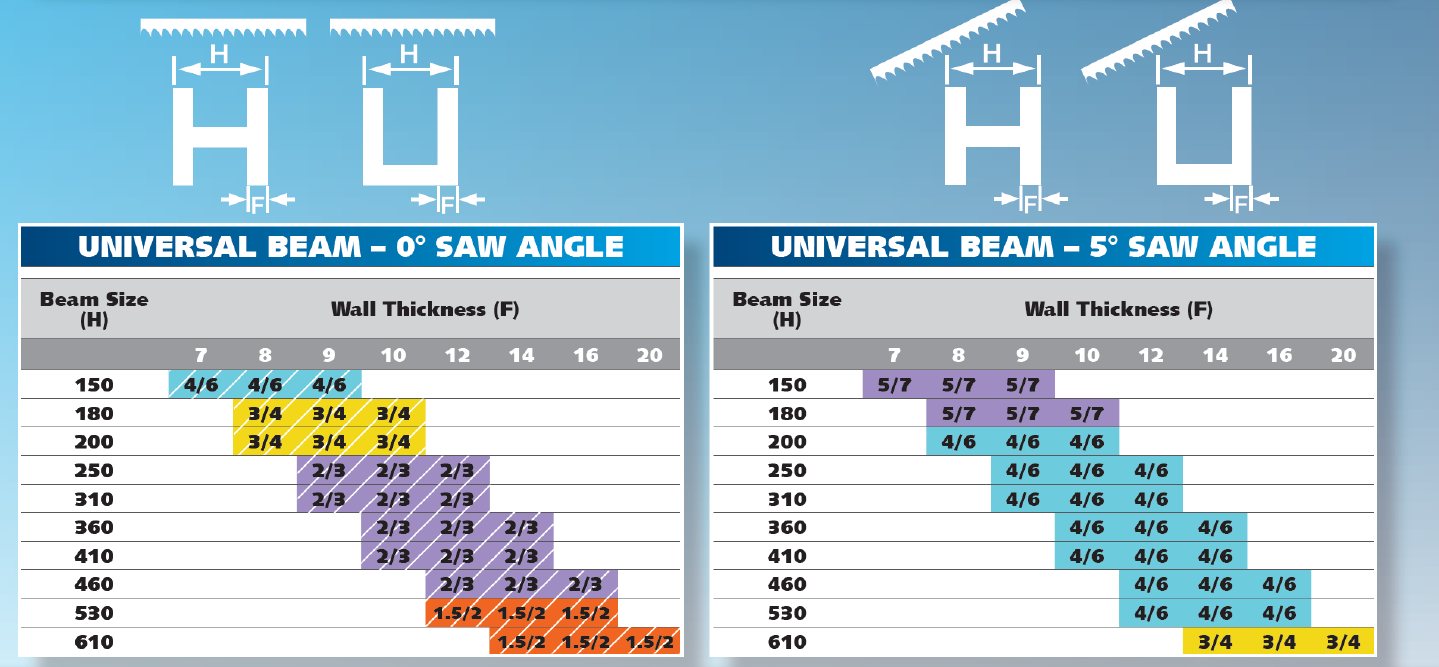

| Materials Cut | Bundled Solids, Thin-walled Tubes, Squared Solids, Thick-walled Tubes, Round Solids, Square Tubes. |

| Cutting Edge Style | Variable |

| For Use With Saw Type | Bandsaws |

Bi-alfa Cobalt M42

Constructed from a high speed strip (HSS) and electron-beam welded to a high-strength spring steel alloy backing material, the blade delivers sheer cutting excellence.

This generates the cutting performance of high-speed steel with the extreme toughness and fatigue resistance of an alloy backing steel.

Why use Bi-alfa cobalt M42 bandsaw blades?

- Significantly faster cutting rates for accelerated productivity

- Exceptional performance with cleaner, smoother cuts

- Patented design reduces tooth strippage and machine downtime

- Excellent heat & wear resistance allowing you to cut for longer and harder

- Increased blade life for reduced production costs and blade spend

- Minimal noise and vibration for improved health and safety

What does the Blade Cut?

Standard order processing/manufacturing time is around 24-48hours

All orders placed before 4:00 pm Melbourne time go into production on the same day and dispatched the following afternoon.

Please Note: Bandsaw blades under the PREMIUM CATEGORY which include "TCT Timber, Carbide Grit and Diamond Coated Bandsaw Blades can take up to 4 weeks to 3 months to be shipped due to high demand and complexity of the production process.

For Enquires, please email [email protected] or phone 03 9005 7931.

- Delivery policy

We will arrange for the products to be delivered to the address for delivery indicated in your order. Each item will be subject to “Signed on Receipt”.

We will use reasonable endeavours to deliver products on the date for delivery set out in our order confirmation or, if no date is set out in our order confirmation, within 7 days of the date of our order confirmation. However, we cannot guarantee delivery by the relevant date.

We do however guarantee that unless there are exceptional circumstances all deliveries of products will be dispatched within 30 days of the later of receipt of payment and the date of our order confirmation

VIC 1 Day

NSW 2 Days

ACT 2 Days

TAS 3 Days

QLD 3 Days

NT 5 Days

SA 2 Days

WA 5 Days

5 out of 5 stars (based on 9 reviews)

Write a Review

Knife Maker

October 8, 2021

Best blades I’ve found to cut out high carbon knife blanks on my vertical bandsaw

A Cut Above

September 3, 2021

Using on AluminIum 1/4″ and smaller. These blades lasted longer and are more durable than any others we have used.

Mild steel

August 19, 2021

Be careful how you lower these blades into the work, especially if its a tube or pipe. You are likely to damage the teeth. A good blade for mild steel.

Always gets the job done!

July 6, 2021

Good quality, fast cutting easy to tension value for money

Over the moon!!!

June 24, 2021

This blade replaced the useless one that came with my bandsaw, much smoother and finer cut.

Bi-alfa Cobalt M42

Lubricating the cutting edge will reduce the heat that is generated by cutting friction – too much heat in the cut is one of the main reasons for blade failure.

A flood of coolant helps wash the chips from the gullets

• Chips become work-hardened in the cutting operation

• If chips are dragged back through the cut a second time, they can damage teeth

A flood of coolant helps cool the blade’s cutting edge and saw guides, extending blade life.

Remember: flood coolant whenever possible and only use coolant where chips are present – do not use coolant on materials that produce a powder, such as gray iron.

Breaking in a new band saw blade hones and strengthens ultra-sharp cutting edges and significantly increases band life.

To break in a bi-metal saw blade, run at the recommended band speed, but reduce the normal cutting rate by about half. (Make sure the band keeps pulling chips. If necessary, increase the feed force until the band does pull chips.) Cut at this reduced rate for about 20 minutes, and then increase the feed force in steps until you attain the normal cutting rate.

To break in a carbide blade, reduce both the band speed and cutting rate by 50% and begin sawing. Increase the band speed and feed force in small steps, but never allow the band to squeal or shriek.

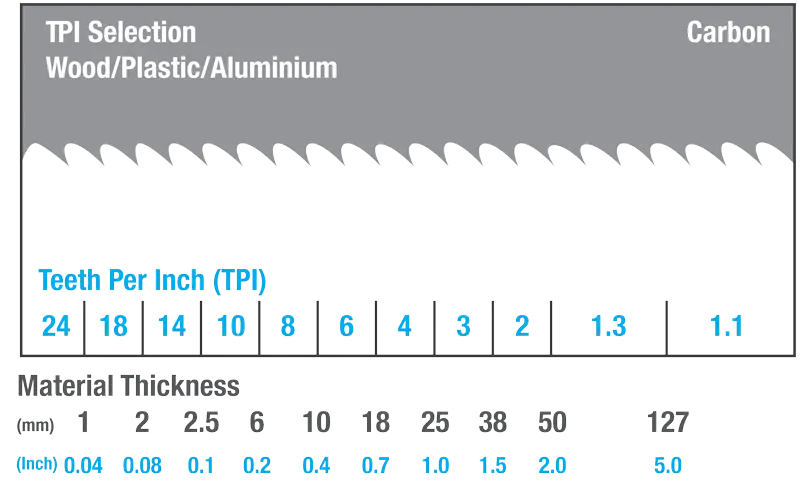

Carbon steel blades are usually the best choice for sawing wood, plastic, aluminum, and similar easy-to-cut materials.

Bi-Metal blades have the best balance of heat resistance, wear resistance, and chip resistance to productively saw most steels and other metals.

Tungsten Carbide blades provide superior heat and wear resistance for sawing extremely tough metals or very abrasive metals and non-metals.

It depends on the material you are cutting, condition of your band saw, speed and duration of production (22 variables…) They typically last 3-5 times as long as a carbon blade

After putting your blade on my machine, it looks like the teeth are pointing the wrong way.

There is an 80/20 rule in the band saw world. 80% of machines are built with the teeth pointing one direction, while 20% are built with the teeth pointing the other. We weld all of our blades to comply with the 80%. Thankfully, there is a simple solution. If your teeth are pointing in the wrong direction, place your hands at 9 and 3 (think of a clock).

While pinching the blade between your fingers and thumbs, rotate your hands so that the blade will flip itself “inside out”. The teeth should now be pointing in the right direction.

• When Cutting Curves, The Width Of The Blade Will Determine The Smallest Radius That May Be Cut

• Wide Blades Are Most Often Used For Resawing Or Straight Line Cuts

• Smaller Width Blades Are Used For Smaller Radius Cuts

Check the blade pitch. If the blade engages fewer than six teeth, those teeth are subject to overloading and stripping, especially under heavy feed force. If the blade engages more than 24 teeth, the chips formed may pack the relatively small gullets and strip teeth.

Any chips drawn back into the cut contribute to gullet packing and stripping. Cutting fluid must prevent chip welding, and the chip brush must clean the gullets as the blade exits the cut.

A workpiece that spins or moves in the saw vise will destroy a blade abruptly.

Yes, they can cut ferrous or nonferrous metals such as aluminum, brass, bronze or steel, stainless steel, titanium.

These blades begin as a bi-metal strip produced by electron- or laser-beam welding a narrow strip of high speed steel to a wider strip of alloy steel. Teeth are cut into the high speed steel edge. The resulting blade has highly heat and wear resistant teeth and a tough, durable backing.

Bimetal blades are metal cutting blades. They are used on band saws to cut carbon steel, tool steel, structural steel, stainless steel, pipes and tubes, die steel, angles and flat stock, and mixed metal applications.

Our clients who use these metal cutting bandsaw blades include steel service centers, small to large manufacturers, fabricators, maintenance shops, job shops, tool and die shops, and anyone interested in saw cutting a broad range of shapes, structures, and solids.

• To Achieve A Smoother, More Refined Cut Choose A Blade That Has More TPI

• The More TPI, The Finer The Cut Will Be; The Fewer Teeth Per Inch, The Rougher The Cut Will Be

• High TPI Configurations Should Be Used On Thinner Materials And May Require A Reduced Material Feed Rate

• Low TPI Configurations Should Be Used On Thicker Materials And May Require A Higher Feed Rate

Material Machinability Rating – The lower the machinability rating the slower the band speed will need to be.

Blade Selection – The cutting edge (tooth tip) of the blade will govern the speed at which the blade can run (FlexBack = Slowest Cutting, Carbide = Fastest Cutting)

Cutting Noise / Vibration – Cutting noise or vibration is a killer to a cutting edge – if either is present, the speed must be decreased

Coolant / Cutting Fluid – If the coolant is adequate, use the standard cutting chart speeds. When cutting dry, reduce the speed by 40-50%

Bimetal band saw blades are available in widths as small as 6mm and as wide as 80mm. On our site, we sell bi metal cutting blades with a length as long or as short as you need them. We custom make them to fit your bandsaw, just tell us what you need

Purchase Your Blade

5 Easy Steps to Build Your Own Sawblade

Welcome to the

Sawblade.com.au

Mobile App

3. Select the Length (Round up to the Closest Increment)(Round up to the Closest Increment)

2. Now Enter the Exact Length in (mm) (Made to your Order)

Length is not correct, changed to maximum allow length.

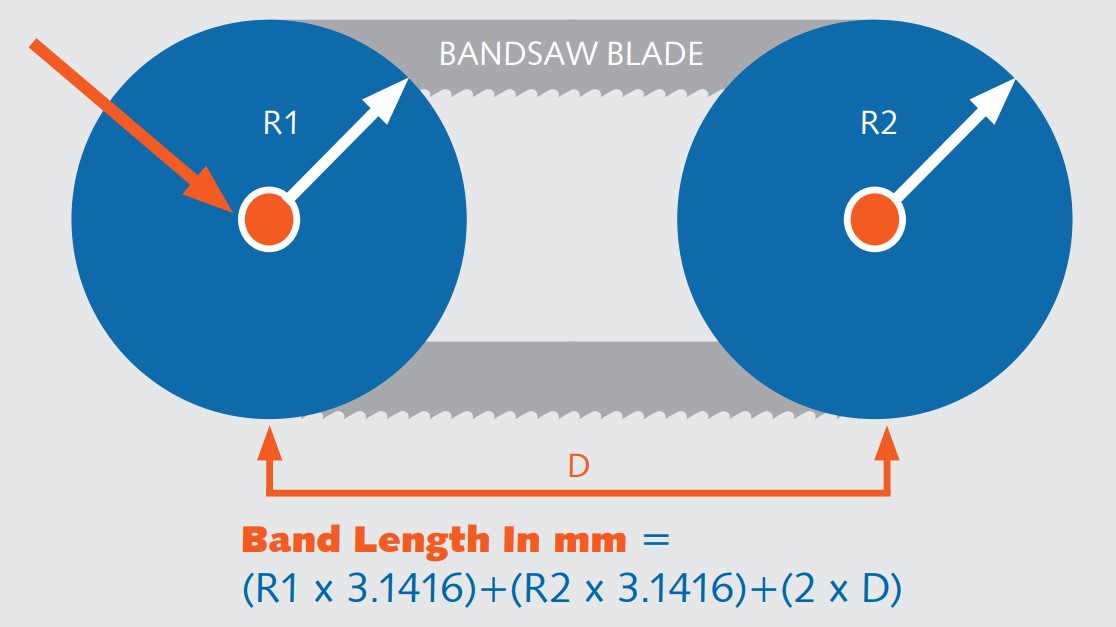

Adjust the wheels of the machine to their correct position (about the middle of the adjustment range)

- Refering to the diagram below, measure the distance between the centre point of each wheel in mm (measurement D).

- Now measure the radius of each wheel in mm (R1 and R2).

- Use this formula to calculate the band length

3. Select the TPI (Teeth Per Inch)

The recommended TPI(s) will be shown automatically for your chosen blade width.

4. Great, Can I have your Name?

5. and your Contact Number?

6. Enter Quantity

Please Click Step 1 to Reload Blade Engine. Step 1

Order Your Blade

Order Details:

Showing 1–12 of 87 results

-

$59.94

$59.94

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$64.25

$64.25

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$71.56

$71.56

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$78.17

$78.17

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$83.48

$83.48

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$88.34

$88.34

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$93.50

$93.50

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$98.38

$98.38

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$103.54

$103.54

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$108.57

$108.57

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$113.87

$113.87

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart -

$119.03

$119.03

Bi-alfa Cobalt M42 6mm Width x 0.9mm Thick x 6 TPI

Add to cart

Shipping Australia Wide

Shipping Australia Wide