Bi-alfa Cobalt Master Supreme

Bi-alfa Cobalt Master Supreme

Basically, Bi-alfa Cobalt Master Supreme has a precise perpendicular cut with an excellent surface finish on the most difficult-to-cut-materials. The doubled- sided chamfered pre-cutter ensures absolute straight cutting, while a pair of lower set finishing teeth keep the cutting channel open. Resulting in a clean and smooth cutting surface.

High Efficiency

HSSCo-M51 tooth tips allow to cut materials with a hardness of up to 50 HRc (1600 N/mm2). Together with an aggressive cutting angle of 16°, it is the ideal combination to cut high alloyed and exotic materials on larger cross sections.

Longer Blade Life

The high heat and mechanical wear resistance of HSSCo-M51 cutting tips ensure excellent blade life, when cutting high alloyed and exotic materials.

This special development consists of ground tooth tips: chamfered pre-cutter and lower finishing tooth tips. The Master-Tooth is particularly suitable for cutting rare and exceptional alloys.

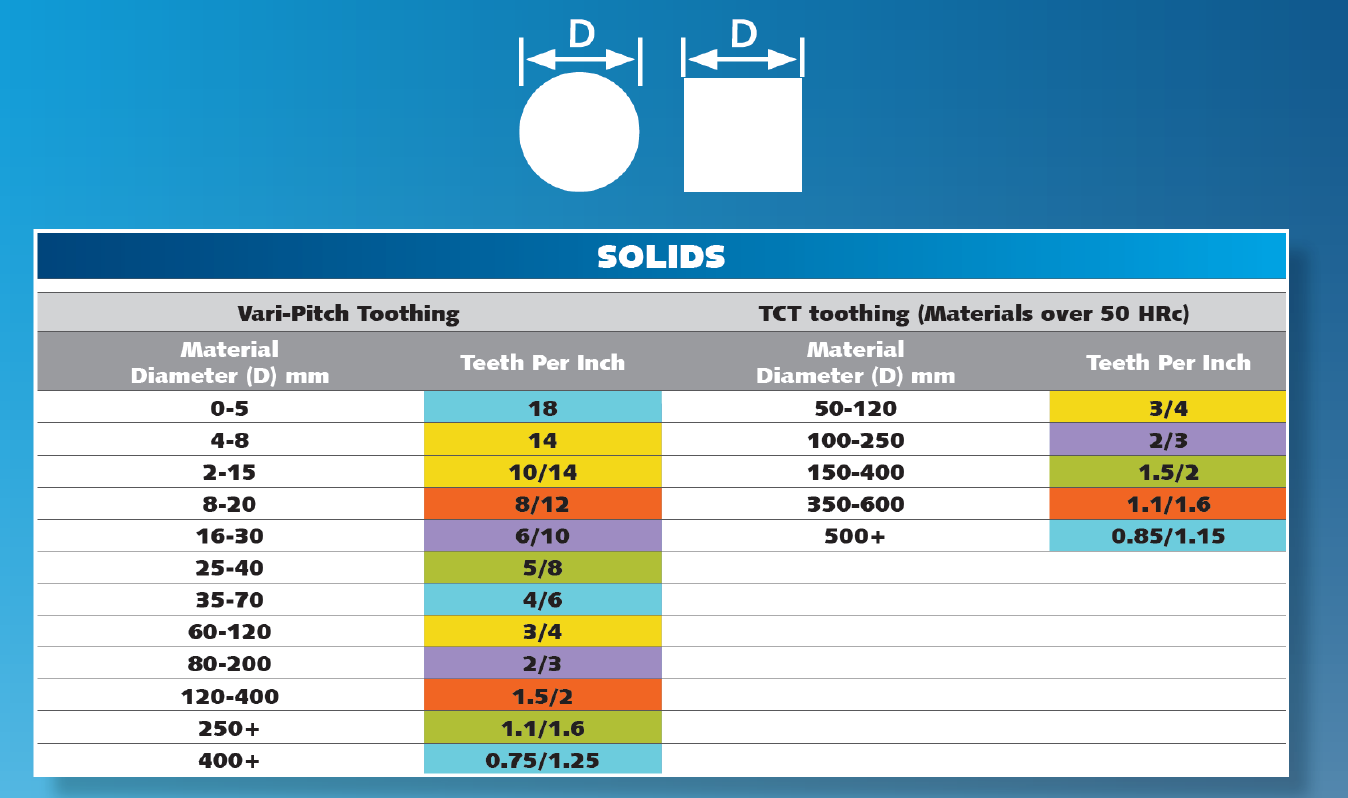

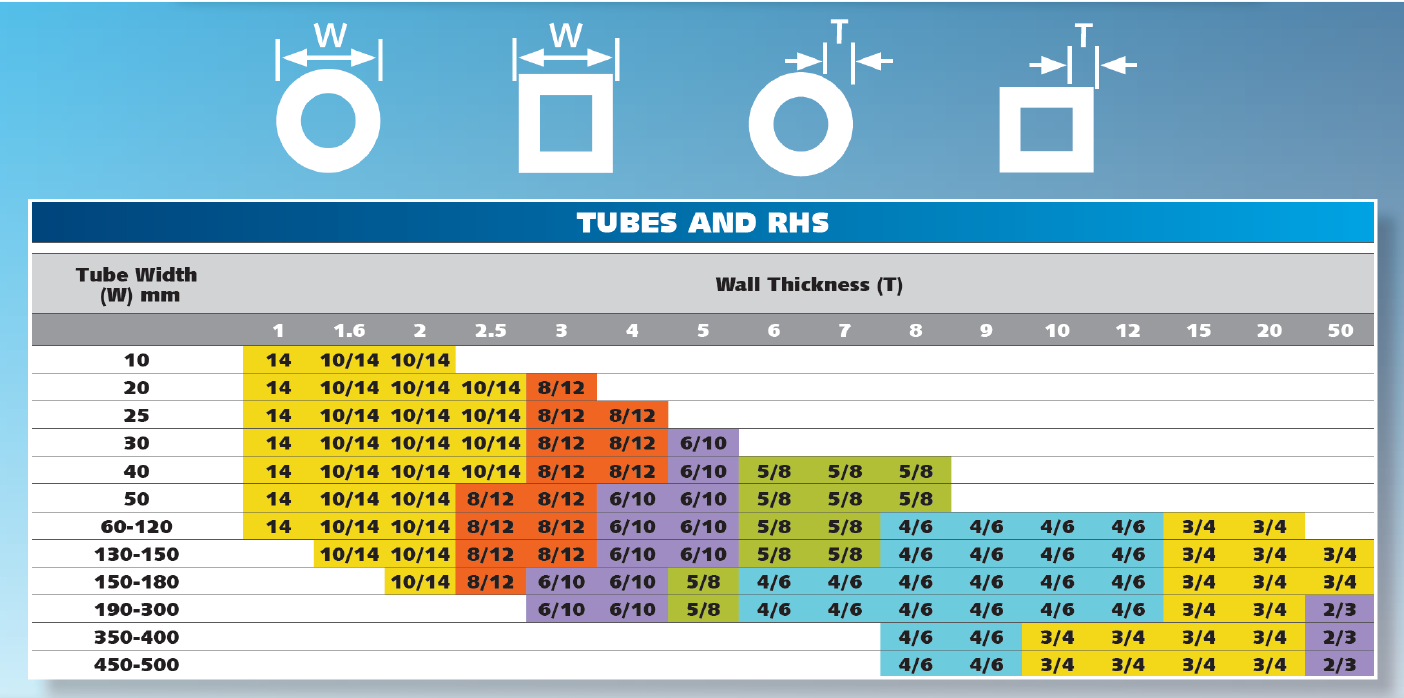

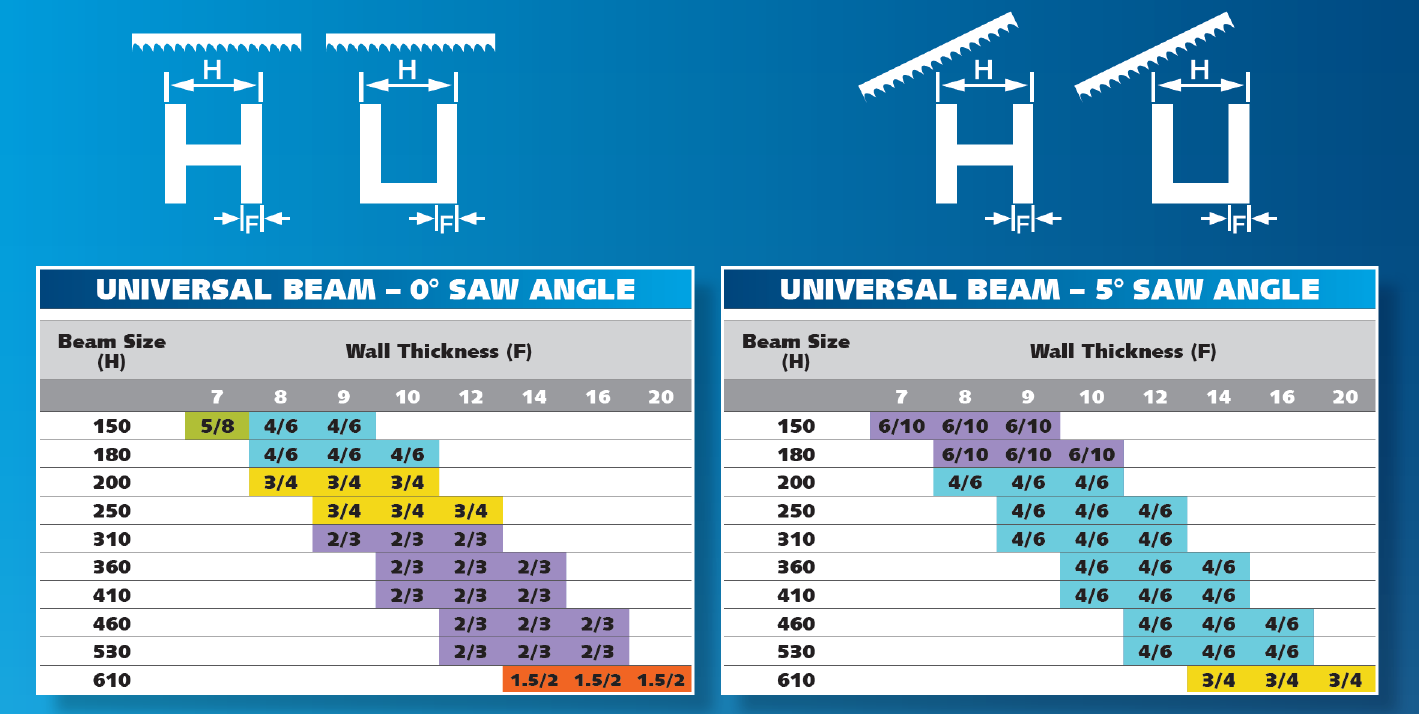

What does the Blade Cut?

Bi-alfa Cobalt Master Supreme

5 out of 5 stars (based on 6 reviews)

Precise perpendicular cuts with excellent surface finish on the most difficult-to-cut-materials. The doubled- sided chamfered pre-cutter ensures absolute straight cutting, while a pair of lower set finishing teeth keep the cutting channel open. Resulting in a clean and smooth cutting surface.

HSSCo-M51 tooth tips allow to cut materials with a hardness of up to 50 HRc (1600 N/mm2). Together with an aggressive cutting angle of 16°, it is the ideal combination to cut high alloyed and exotic materials on larger cross sections.

The high heat and mechanical wear resistance of HSSCo-M51 cutting tips ensure excellent blade life, when cutting high alloyed and exotic materials.

-

Free Shipping

over $350 Australia wide

Free Shipping

over $350 Australia wide

-

Manufactured

Manufactured

in Australia Purchase Direct -

100% Safety

Only Secure Payments

100% Safety

Only Secure Payments

-

Australia Wide Shipping Only

LIVE: Orders Placed Today

Australia Wide Shipping Only

LIVE: Orders Placed Today

Talk to our Blade Expert

Get in Touch!

Request a Blade Specialist to give you a Call

Technical Specifications

| Item | Bi-alfa Cobalt Master Supreme |

| Materials Cut | Plates, Round Solids, Squared Solids |

| Cutting Edge Style | Variable |

| For Use With Saw Type | Bandsaws |

Bi-alfa Cobalt Master Supreme

Precise perpendicular cuts with excellent surface finish on the most difficult-to-cut-materials. The doubled- sided chamfered pre-cutter ensures absolute straight cutting, while a pair of lower set finishing teeth keep the cutting channel open. Resulting in a clean and smooth cutting surface.

High Efficiency

HSSCo-M51 tooth tips allow to cut materials with a hardness of up to 50 HRc (1600 N/mm2). Together with an aggressive cutting angle of 16°, it is the ideal combination to cut high alloyed and exotic materials on larger cross sections.

Longer Blade Life

The high heat and mechanical wear resistance of HSSCo-M51 cutting tips ensure excellent blade life, when cutting high alloyed and exotic materials.

This special development consists of ground tooth tips: chamfered pre-cutter and lower finishing tooth tips. The Master-Tooth is particularly suitable for cutting rare and exceptional alloys.

What does the Blade Cut?

Standard order processing/manufacturing time is around 24-48hours

All orders placed before 4:00 pm Melbourne time go into production on the same day and dispatched the following afternoon.

Please Note: Bandsaw blades under the PREMIUM CATEGORY which include "TCT Timber, Carbide Grit and Diamond Coated Bandsaw Blades can take up to 4 weeks to 3 months to be shipped due to high demand and complexity of the production process.

For Enquires, please email [email protected] or phone 03 9005 7931.

- Delivery policy

We will arrange for the products to be delivered to the address for delivery indicated in your order. Each item will be subject to “Signed on Receipt”.

We will use reasonable endeavours to deliver products on the date for delivery set out in our order confirmation or, if no date is set out in our order confirmation, within 7 days of the date of our order confirmation. However, we cannot guarantee delivery by the relevant date.

We do however guarantee that unless there are exceptional circumstances all deliveries of products will be dispatched within 30 days of the later of receipt of payment and the date of our order confirmation

VIC 1 Day

NSW 2 Days

ACT 2 Days

TAS 3 Days

QLD 3 Days

NT 5 Days

SA 2 Days

WA 5 Days

5 out of 5 stars (based on 3 reviews)

Write a Review

cuts beautifully!

October 10, 2022

It works, cuts straight and fast

will order again

October 10, 2022

Cuts very nicely

Recommended shop!

October 10, 2022

Left very smooth finish

Excellent Quality

October 10, 2022

Found this blade to very good quality.

The real deal!

May 3, 2022

I always have good luck with your blades So when I needed to replace my current ones, these seemed like a great deal. So far I’ve only worn out one, on a job cutting quite a bit of 1/8” steel square tubing. Long ago I’d used cheaper blades, and the teeth would be knocked off in 2 cuts . These worked really well for me.

Purchase Your Blade

5 Easy Steps to Build Your Own Sawblade

Welcome to the

Sawblade.com.au

Mobile App

3. Select the Length (Round up to the Closest Increment)(Round up to the Closest Increment)

2. Now Enter the Exact Length in (mm) (Made to your Order)

Length is not correct, changed to maximum allow length.

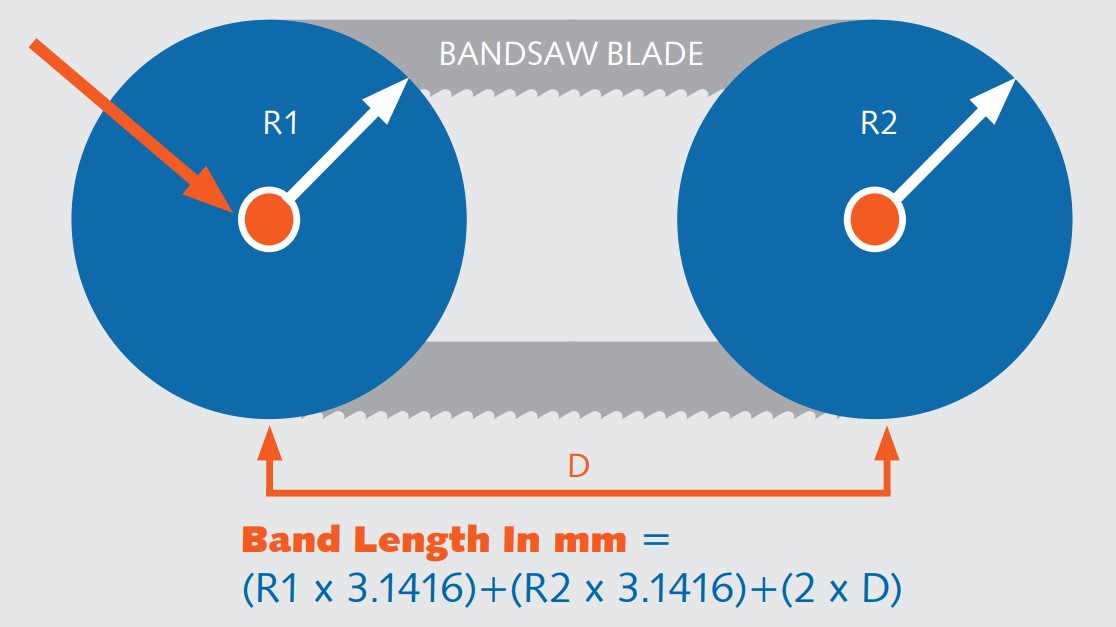

Adjust the wheels of the machine to their correct position (about the middle of the adjustment range)

- Refering to the diagram below, measure the distance between the centre point of each wheel in mm (measurement D).

- Now measure the radius of each wheel in mm (R1 and R2).

- Use this formula to calculate the band length

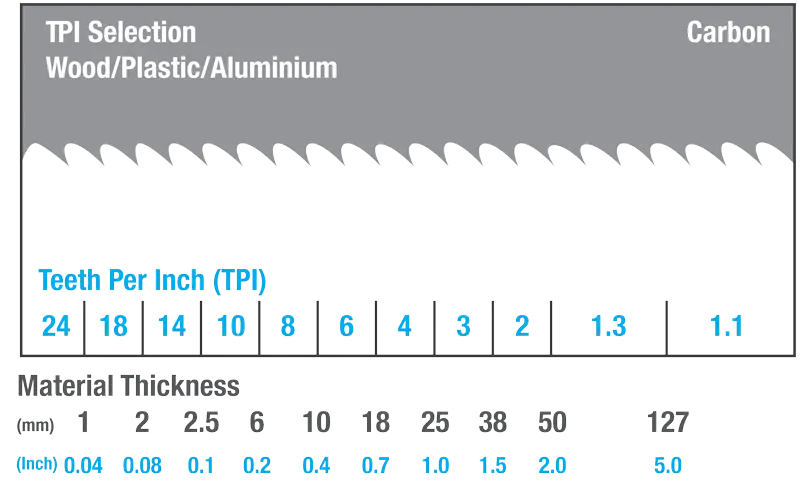

3. Select the TPI (Teeth Per Inch)

The recommended TPI(s) will be shown automatically for your chosen blade width.

4. Great, Can I have your Name?

5. and your Contact Number?

6. Enter Quantity

Please Click Step 1 to Reload Blade Engine. Step 1

Order Your Blade

Order Details:

Showing 1–12 of 87 results

-

$105.84

$105.84

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$115.17

$115.17

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$123.77

$123.77

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$132.81

$132.81

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$141.70

$141.70

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$150.45

$150.45

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$158.91

$158.91

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$167.66

$167.66

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$176.56

$176.56

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$185.59

$185.59

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$194.18

$194.18

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart -

$202.80

$202.80

Bi-alfa Cobalt Master Supreme 34mm Width x 1.1mm Thick x 2/3 TPI

Add to cart

Shipping Australia Wide

Shipping Australia Wide