Carbon Ripper Blades

Carbon Ripper Blades

High quality carbon steel blade for primary processing and timber-ripping applications.

- Made from Carbon-Rich Italian Steel

- Band Widths from 20mm-54mm

- Smooth Surface Finish

- Suitable for High Production

- Not suitable on super hardwoods

- Not suitable on Sleepers

What does the Blade Cut?

Carbon Ripper Blades

5 out of 5 stars (based on 4 reviews)

High quality carbon steel blade for primary processing and timber-ripping applications.

- Cost-effective blade – Reduced production costs

- Strong and flexible workhorse – Maximum cutting power

- Fully ground tooth profile – unparalleled “out-of-the-box” performance

-

Free Shipping

over $350 Australia wide

Free Shipping

over $350 Australia wide

-

Manufactured

Manufactured

in Australia Purchase Direct -

100% Safety

Only Secure Payments

100% Safety

Only Secure Payments

-

Australia Wide Shipping Only

LIVE: Orders Placed Today

Australia Wide Shipping Only

LIVE: Orders Placed Today

Talk to our Blade Expert

Get in Touch!

Request a Blade Specialist to give you a Call

Technical Specifications

| Item | Carbon Ripper Blade |

| Materials Cut | Wood/Timber |

| Cutting Edge Style | Variable |

| For Use With Saw Type | Bandsaws |

Carbon Ripper Blades

High quality carbon steel blade for primary processing and timber-ripping applications.

- Made from Carbon-Rich Italian Steel

- Band Widths from 20mm-54mm

- Smooth Surface Finish

- Suitable for High Production

- Not suitable on super hardwoods

- Not suitable on Sleepers

What does the Blade Cut?

Standard order processing/manufacturing time is around 24-48hours

All orders placed before 4:00 pm Melbourne time go into production on the same day and dispatched the following afternoon.

Please Note: Bandsaw blades under the PREMIUM CATEGORY which include "TCT Timber, Carbide Grit and Diamond Coated Bandsaw Blades can take up to 4 weeks to 3 months to be shipped due to high demand and complexity of the production process.

For Enquires, please email [email protected] or phone 03 9005 7931.

- Delivery policy

We will arrange for the products to be delivered to the address for delivery indicated in your order. Each item will be subject to “Signed on Receipt”.

We will use reasonable endeavours to deliver products on the date for delivery set out in our order confirmation or, if no date is set out in our order confirmation, within 7 days of the date of our order confirmation. However, we cannot guarantee delivery by the relevant date.

We do however guarantee that unless there are exceptional circumstances all deliveries of products will be dispatched within 30 days of the later of receipt of payment and the date of our order confirmation

VIC 1 Day

NSW 2 Days

ACT 2 Days

TAS 3 Days

QLD 3 Days

NT 5 Days

SA 2 Days

WA 5 Days

5 out of 5 stars (based on 4 reviews)

Write a Review

5 Star Quality :D

November 14, 2021

The only bad thing I can say about this blade is that after less than one year on the job it broke right in the weld. Normally a weld is tougher than the metal itself, so am at a loss as to what happened. Otherwise, this blade cuts fast, straight and clean.

Top notch

September 17, 2021

Ordered a dozen, blades cut better than ones I got from my area. Top notch service , Thank you.

Very Good Service

August 27, 2021

Fast shipping, quality ripping blades, 1 of the blades was damaged called customer service – blade was replaced within a few days.

Will be back

March 8, 2021

Stays sharp till the blade finally breaks. The cuts are straight and true. Also cuts faster and with more under greater force than other blades we’ve tried. Will buy more

Carbon Ripper Blades

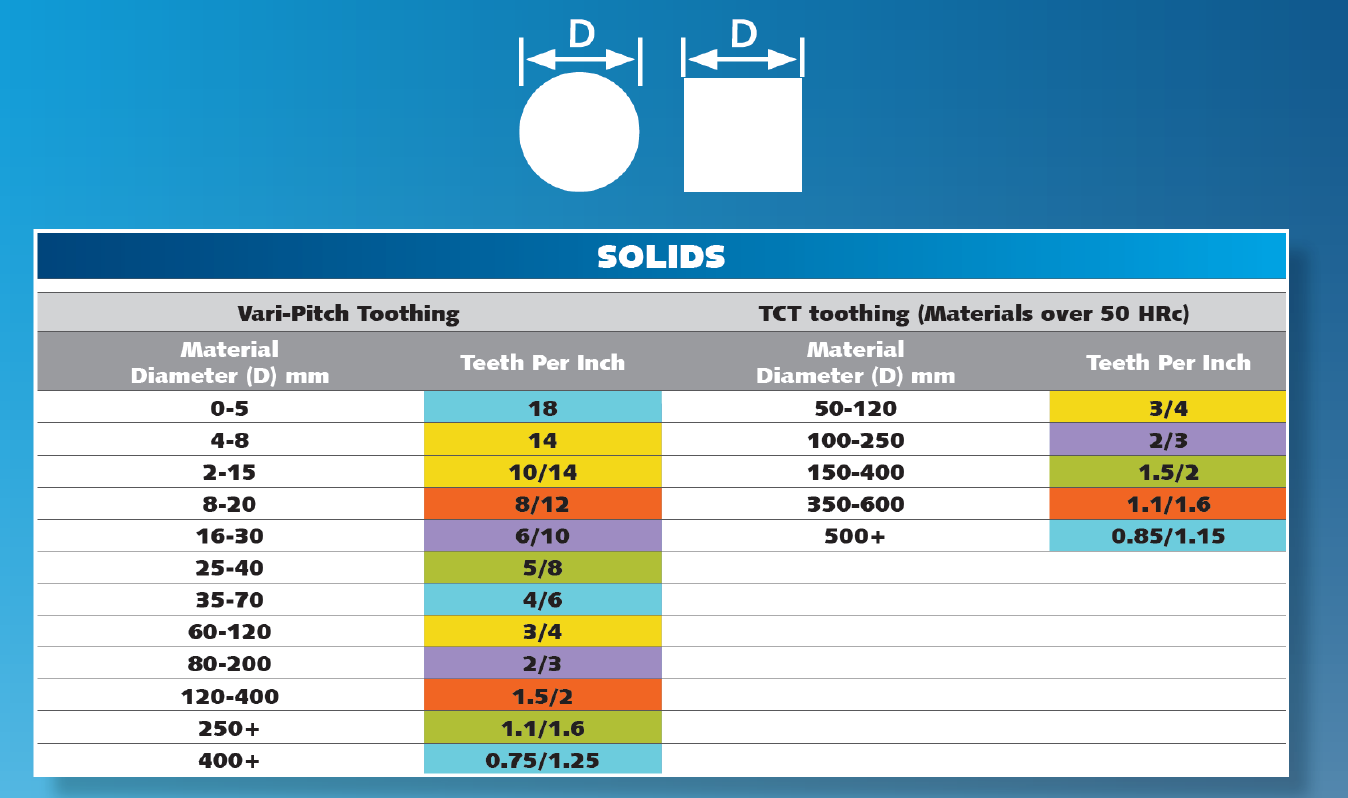

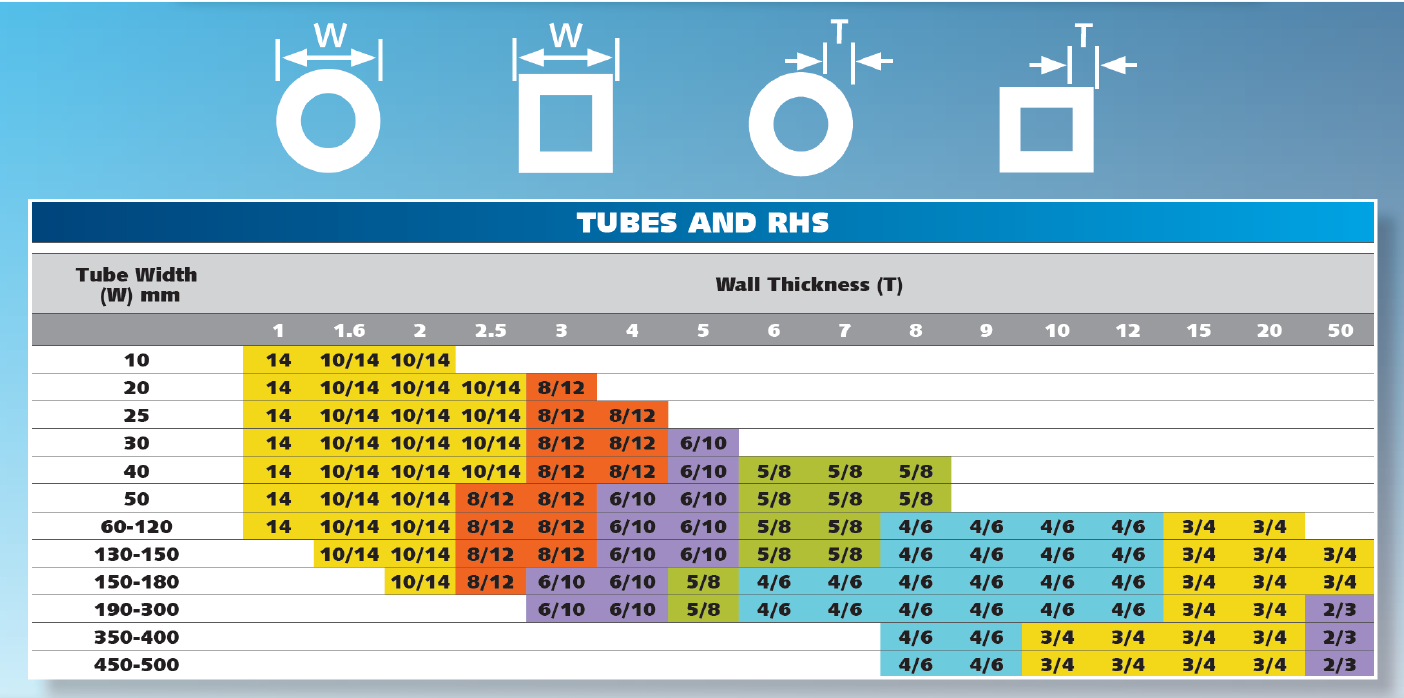

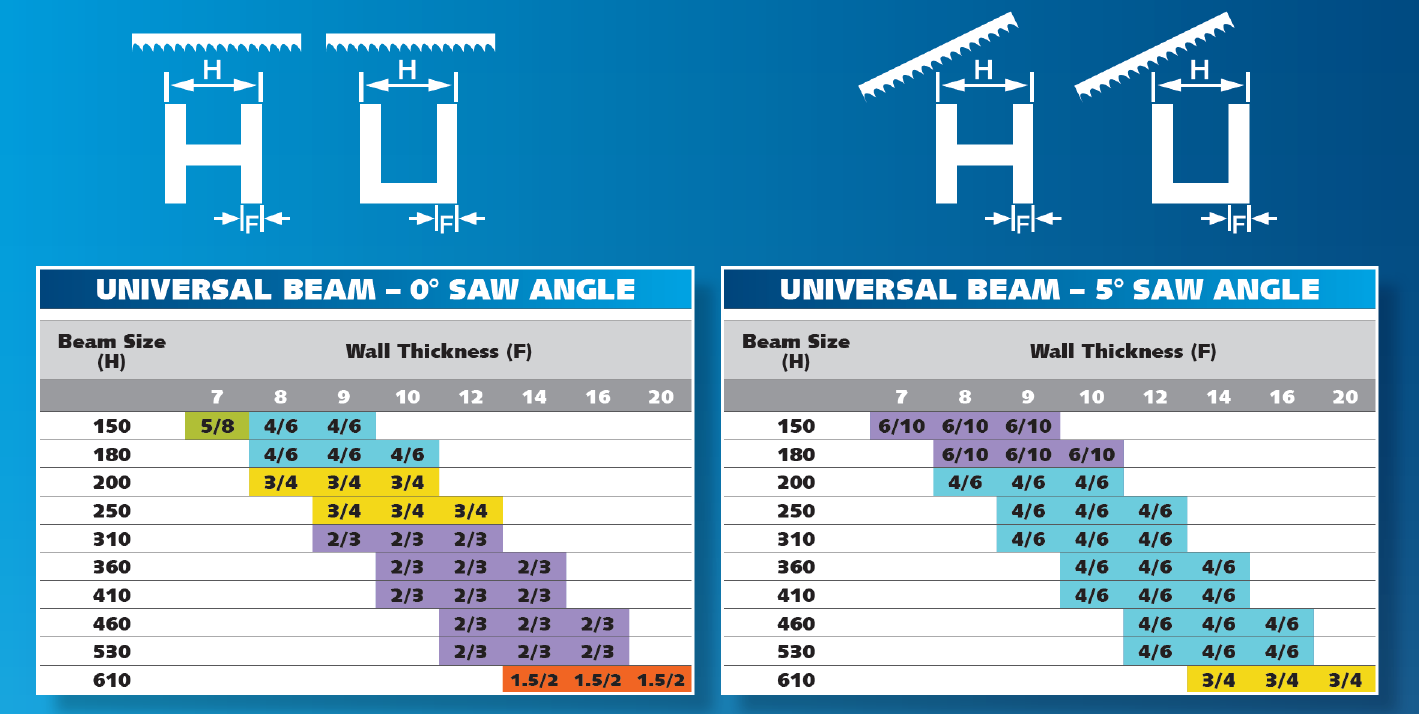

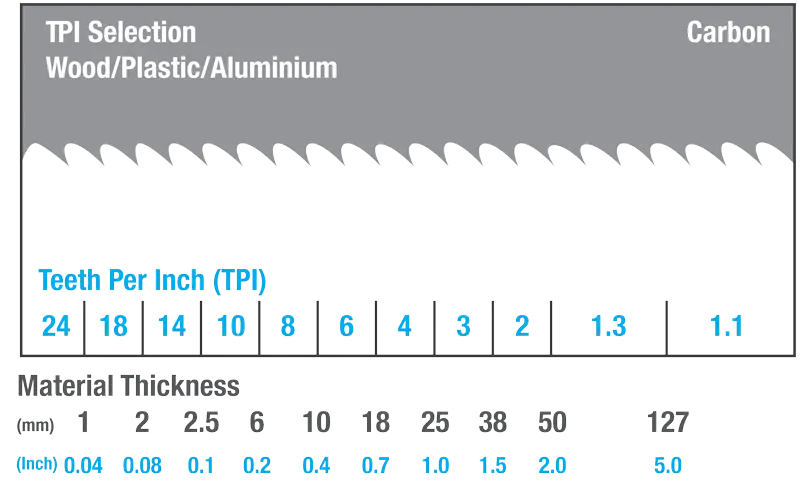

Generally, the higher the amount of saw blade teeth, the better the quality of cut and finishing. If you’re looking for a faster and rougher cut, then a blade with fewer teeth will be more suitable.

For example, if you are cutting aluminium or a high quality finish when cutting laminate, you will want a higher number of teeth compared to blades for soft wood.

When blades have fewer teeth, they have deeper gullets (space in between teeth) which creates a more aggressive chiselling action.

A band saw can be used to cut curves, even in thick lumber, such as in creating cabriole legs, to rip lumber and to crosscut short pieces. The most common use for the band saw, however, is in cutting irregular shapes.

The second most common use is in resawing or ripping lumber into thinner slabs.14 Apr 2009

You should be able to sharpen your blade two or three times before needing to replace it, but sometimes breakage happens. Blade breakage can result from a range of situations. Common causes of blade breakage include: Dull teeth.

It’s really something that takes a little time to get a feel for. At some point, you will realize you have to push much harder than you used to for something as simple as a ripping operation.

You will also notice more burning on woods that didn’t burn before. In addition, you should notice more tearout on your cuts. If you don’t notice any of these changes, or they just aren’t that severe yet, then the blade is still sharp. The first time you notice these things, clean the blade. After 2-3 cleanings it’s time for a resharpening.

Carbon steel is the most common cost effective metal used to manufacture sawmill blades and performs well for high production.

Bi-Metal steel has been gaining popularity due to its durability and heat resistance, which keeps the blades sharp longer. They typically last 10x longer than carbon steel ones but come at a higher price.

When it comes to ripping – the coarser the better . a range between 1 to 2 TPI is recommended.

Purchase Your Blade

5 Easy Steps to Build Your Own Sawblade

Welcome to the

Sawblade.com.au

Mobile App

3. Select the Length (Round up to the Closest Increment)(Round up to the Closest Increment)

2. Now Enter the Exact Length in (mm) (Made to your Order)

Length is not correct, changed to maximum allow length.

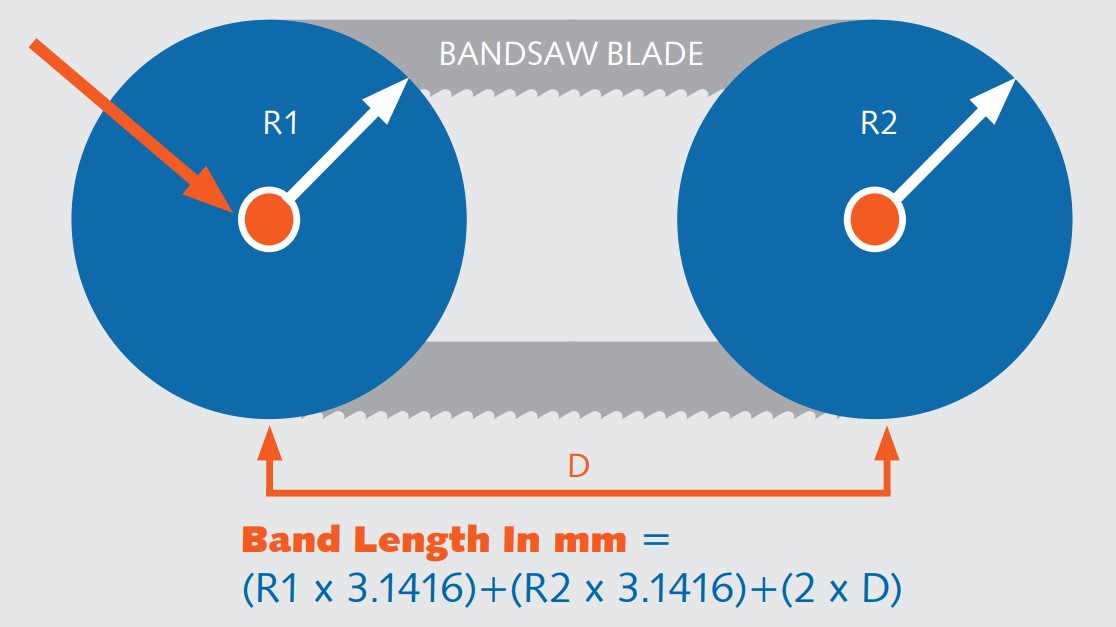

Adjust the wheels of the machine to their correct position (about the middle of the adjustment range)

- Refering to the diagram below, measure the distance between the centre point of each wheel in mm (measurement D).

- Now measure the radius of each wheel in mm (R1 and R2).

- Use this formula to calculate the band length

3. Select the TPI (Teeth Per Inch)

The recommended TPI(s) will be shown automatically for your chosen blade width.

4. Great, Can I have your Name?

5. and your Contact Number?

Select Your Delivery Location

Delivery To:

Express Shipping Best for Small Orders

Order Details:

Bulk Pricing Best for Large Orders

Order Details:

Showing 1–12 of 98 results

-

$75.25

$75.25

Ripper37 Carbon Bandsaw 2290mm x 20mm x 2

Add to cart -

$75.25

$75.25

Ripper37 Carbon Bandsaw 2290mm x 20mm x 1.1

Add to cart -

$75.25

$75.25

Ripper37 Carbon Bandsaw 2290mm x 27mm x 0.9 x 1.3

Add to cart -

$75.25

$75.25

Ripper37 Carbon Bandsaw 2290mm x 27mm x 0.9 x 2

Add to cart -

$87.73

$87.73

Ripper37 Carbon Bandsaw 2290mm x 34mm x 1.1 x 1.1

Add to cart -

$106.63

$106.63

Ripper37 Carbon Bandsaw 2290mm x 41mm x 1.1 x 1.1

Add to cart -

$159.82

$159.82

Ripper37 Carbon Bandsaw 2290mm x 54mm x 1.1 x 1.1

Add to cart -

$86.14

$86.14

Ripper37 Carbon Bandsaw 2745mm x 20mm x 1.1

Add to cart -

$86.14

$86.14

Ripper37 Carbon Bandsaw 2745mm x 20mm x 2

Add to cart -

$86.14

$86.14

Ripper37 Carbon Bandsaw 2745mm x 27mm x 0.9 x 1.3

Add to cart -

$86.14

$86.14

Ripper37 Carbon Bandsaw 2745mm x 27mm x 0.9 x 2

Add to cart -

$102.23

$102.23

Ripper37 Carbon Bandsaw 2745mm x 34mm x 1.1 x 1.1

Add to cart

Shipping Australia Wide

Shipping Australia Wide