TCT Wood Bandsaw Blade

TCT Wood Bandsaw Blade

Basically, a high-performance ripping and resawing tungsten-tipped blade for the ultimate TCT Wood Bandsaw.

Primarily, TCT Timber blades are designed for deep ripping and ultra-fine resawing, allowing you to effortlessly craft the finest veneers. C4 carbide tips are extremely durable and ideal for hardwoods.

Features:

Each tooth on the blade is hardened making it resistant to heat build-up, increasing blade life and strength.

Unique heat line on the back of the blade – the blade does not buckle in use giving you a straighter cut.

Tooth shaped with a chip-breaker – removing waste more efficiently, reducing heat build-up, improving, and extending cutting performance.

Increased hook angle – cuts more aggressively but still leaves a smooth finish, making the cuts faster and easier to control.

Thin gauge (kerf) – Just like thin kerf circular saw blades, it takes less power to drive, with less waste, so deeper cuts are quicker & easier than before.

Increased set of the tooth – standard tooth set does not affect hardwood cutting but can affect cutting resinous timbers such as Pine. With a greater set, these blades handle a wider range of materials.

Butt-welded – the strongest method of welding.

Area Of Application

TCT Wood Bandsaw Blade

5 out of 5 stars (based on 1 review)

It is an ultimate high-performance Ripping & Resawing Tungsten-tipped blade.

Primarily, TCT Timber blades are designed for deep ripping and ultra-fine resawing, allowing you to effortlessly craft the finest veneers. C4 carbide tips are extremely durable and ideal for hardwoods.

-

Free Shipping

over $350 Australia wide

Free Shipping

over $350 Australia wide

-

Manufactured

Manufactured

in Australia Purchase Direct -

100% Safety

Only Secure Payments

100% Safety

Only Secure Payments

-

Australia Wide Shipping Only

LIVE: Orders Placed Today

Australia Wide Shipping Only

LIVE: Orders Placed Today

Talk to our Blade Expert

Get in Touch!

Request a Blade Specialist to give you a Call

Technical Specifications

| Item | TCT Wood Bandsaw Blade |

| Materials Cut | Super Hard Wood, Timber, Exotic Material |

| Cutting Edge Style | Variable |

| For Use With Saw Type | Bandsaws |

TCT Wood Bandsaw Blade

Ultimate high-performance Ripping & Resawing Tungsten-tipped blade.

The TCT Timber blade is specifically designed for deep ripping and ultra-fine resawing, allowing you to craft the finest veneers with ease. Extremely durable with C4 carbide tips, these are perfect for hardwoods or exotics: extremely high performers that we guarantee will never break on the weld.

Features:

Each tooth on the blade is hardened making it resistant to heat build-up, increasing blade life and strength.

Unique heat line on the back of the blade – the blade does not buckle in use giving you a straighter cut.

Tooth shaped with a chip-breaker – removing waste more efficiently, reducing heat build-up, improving, and extending cutting performance.

Increased hook angle – cuts more aggressively but still leaves a smooth finish, making the cuts faster and easier to control.

Thin gauge (kerf) – Just like thin kerf circular saw blades, it takes less power to drive, with less waste, so deeper cuts are quicker & easier than before.

Increased set of tooth – standard tooth set does not affect hardwood cutting but can affect cutting resinous timbers such as Pine. With a greater set, these blades handle a wider range of materials.

Butt-welded – the strongest method of welding.

Area Of Application

Standard order processing/manufacturing time is around 24-48hours

All orders placed before 4:00 pm Melbourne time go into production on the same day and dispatched the following afternoon.

Please Note: Bandsaw blades under the PREMIUM CATEGORY which include "TCT Timber, Carbide Grit and Diamond Coated Bandsaw Blades can take up to 4 weeks to 3 months to be shipped due to high demand and complexity of the production process.

For Enquires, please email [email protected] or phone 03 9005 7931.

- Delivery policy

We will arrange for the products to be delivered to the address for delivery indicated in your order. Each item will be subject to “Signed on Receipt”.

We will use reasonable endeavours to deliver products on the date for delivery set out in our order confirmation or, if no date is set out in our order confirmation, within 7 days of the date of our order confirmation. However, we cannot guarantee delivery by the relevant date.

We do however guarantee that unless there are exceptional circumstances all deliveries of products will be dispatched within 30 days of the later of receipt of payment and the date of our order confirmation

VIC 1 Day

NSW 2 Days

ACT 2 Days

TAS 3 Days

QLD 3 Days

NT 5 Days

SA 2 Days

WA 5 Days

5 out of 5 stars (based on 1 review)

Write a Review

Ate Through Hard Maple

November 9, 2021

We had to resaw 150 year old reclaimed hard maple. This blade ate through it and a lot of hidden nails! Would recommend to anyone that needs to mill a lot of hardwood

Purchase Your Blade

5 Easy Steps to Build Your Own Sawblade

Welcome to the

Sawblade.com.au

Mobile App

3. Select the Length (Round up to the Closest Increment)(Round up to the Closest Increment)

2. Now Enter the Exact Length in (mm) (Made to your Order)

Length is not correct, changed to maximum allow length.

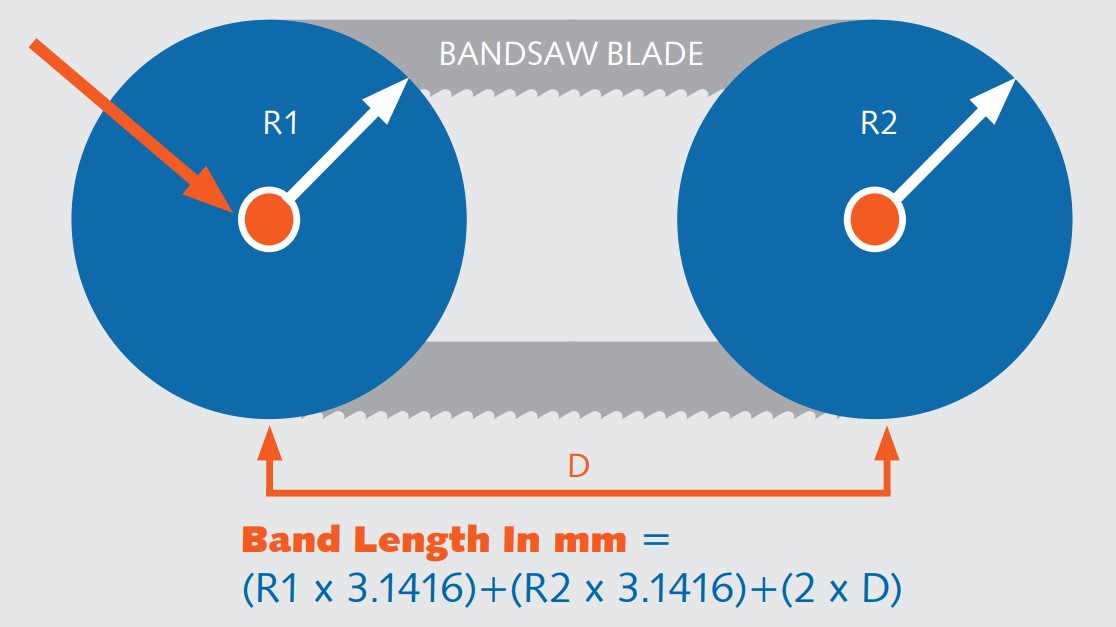

Adjust the wheels of the machine to their correct position (about the middle of the adjustment range)

- Refering to the diagram below, measure the distance between the centre point of each wheel in mm (measurement D).

- Now measure the radius of each wheel in mm (R1 and R2).

- Use this formula to calculate the band length

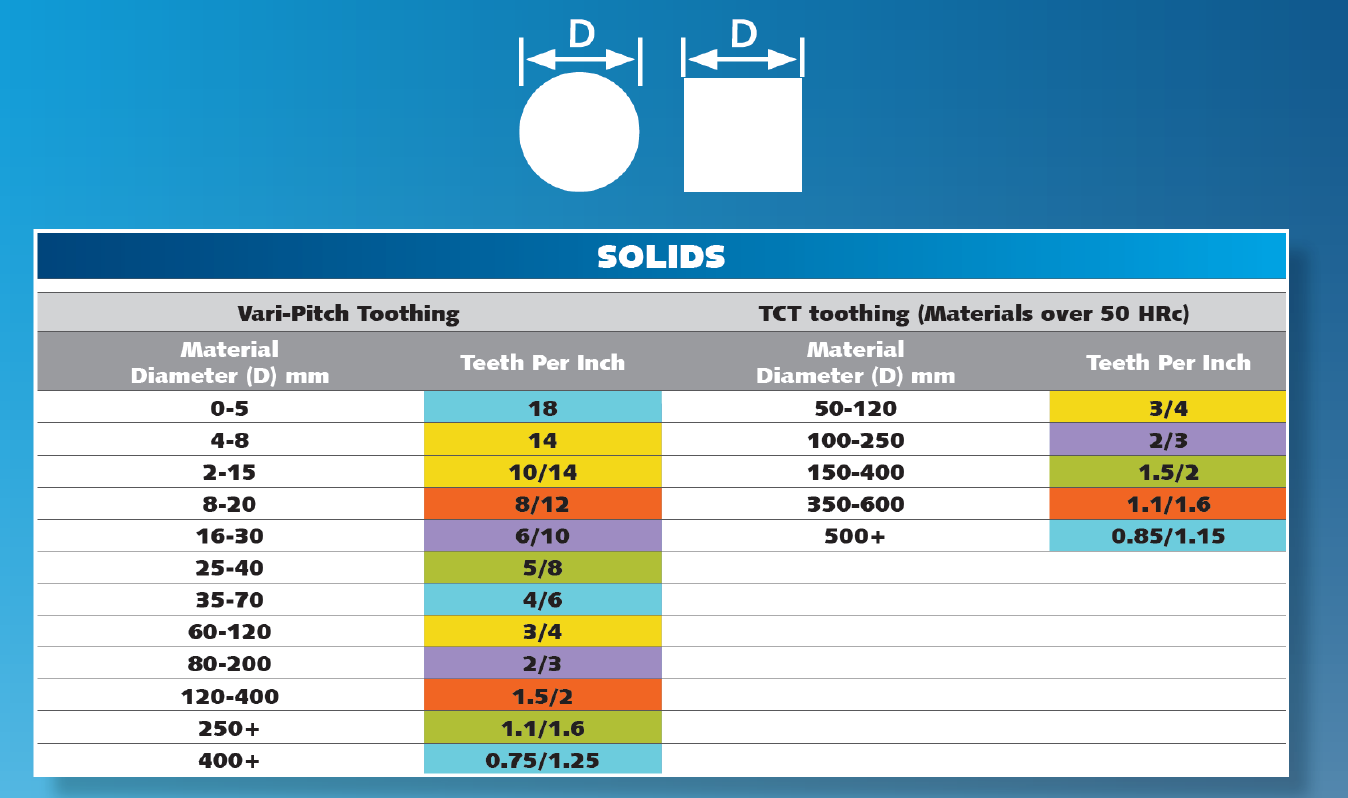

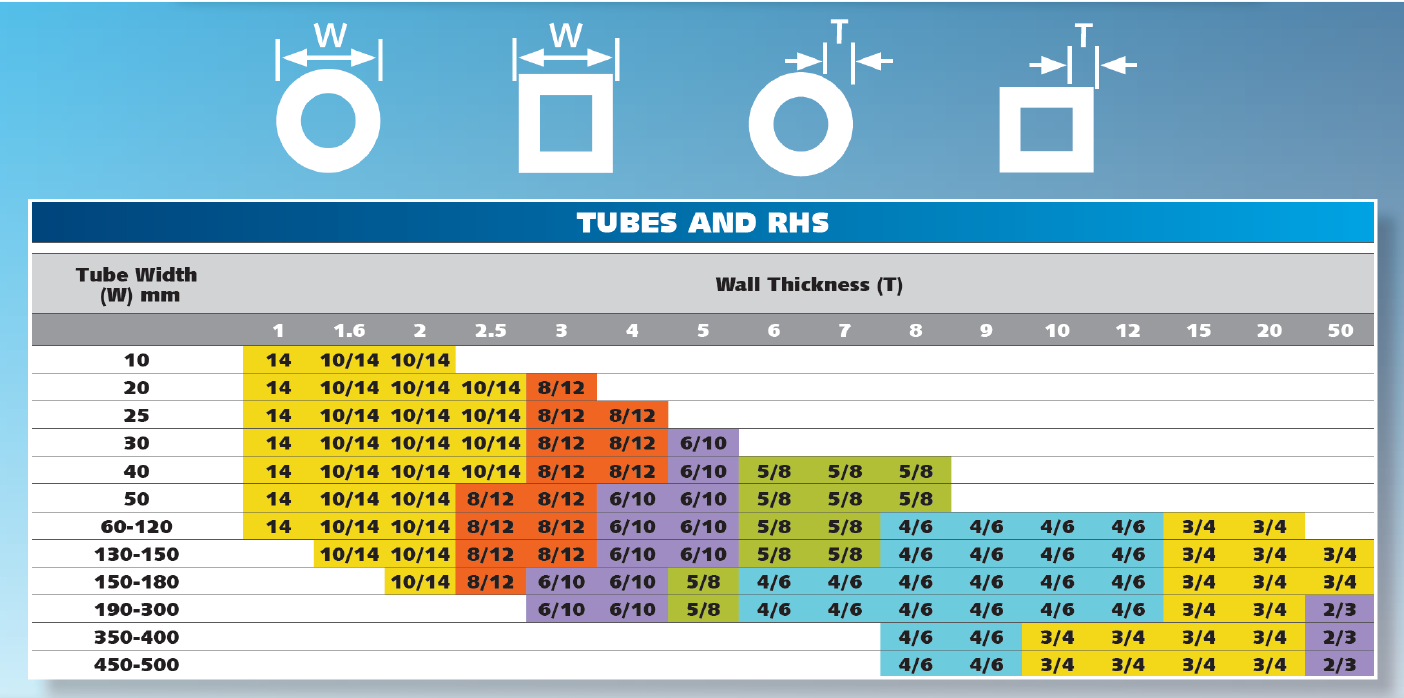

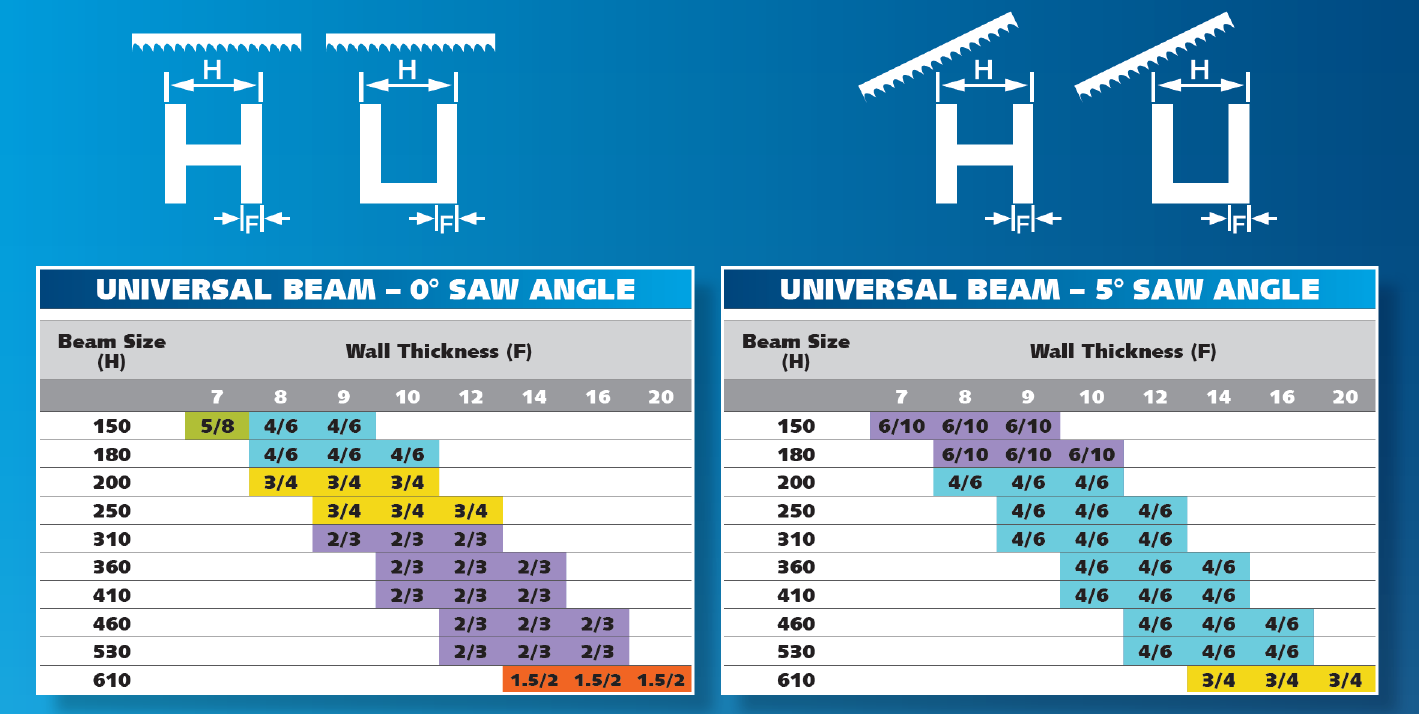

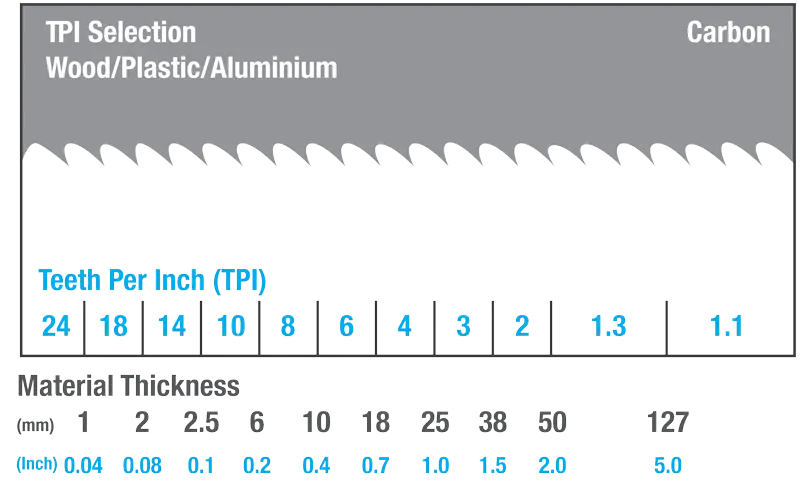

3. Select the TPI (Teeth Per Inch)

The recommended TPI(s) will be shown automatically for your chosen blade width.

4. Great, Can I have your Name?

5. and your Contact Number?

6. Enter Quantity

Please Click Step 1 to Reload Blade Engine. Step 1

Order Your Blade

Order Details:

Showing the single result

Shipping Australia Wide

Shipping Australia Wide