Meat & Fish Cutting Bandsaw Blades

Meat & Fish Cutting Bandsaw Blades

This blade is a precision-ground, hard-tooth bright carbon steel blade for food processing.

The razor-sharp hook teeth allow for maximum penetration while the unique, process-specific tooth set reduces waste for superior yield.

This sturdy blade can be used for a wide range of applications, including carcass-splitting and fresh or frozen meat cutting.

Suitable for cutting:

- Carcass splitting

- Fish

- Frozen fish or meat

- Meat

- Poultry

Benefits

- Superior yield, reducing product waste

- Cleaner cuts

- Food-grade oil coating for safe and immediate use

- Minimum downtime for longer production runs

What does the Blade Cut?

Meat & Fish Cutting Bandsaw Blades

5 out of 5 stars (based on 4 reviews)

This blade is a precision-ground, hard-tooth bright carbon steel blade for food processing.

Suitable for cutting:

- Carcass splitting

- Fish

- Frozen fish or meat

- Meat

- Poultry

-

Free Shipping

over $350 Australia wide

Free Shipping

over $350 Australia wide

-

Manufactured

Manufactured

in Australia Purchase Direct -

100% Safety

Only Secure Payments

100% Safety

Only Secure Payments

-

Australia Wide Shipping Only

LIVE: Orders Placed Today

Australia Wide Shipping Only

LIVE: Orders Placed Today

Talk to our Blade Expert

Get in Touch!

Request a Blade Specialist to give you a Call

Technical Specifications

| Item | Meat & Fish Cutting Bandsaw Blades |

| Materials Cut | Carcass Splitting, Fish, Frozen Fish or Meat, Meat, Poultry |

| Cutting Edge Style | Variable |

| For Use With Saw Type | Bandsaws |

Meat & Fish Cutting Bandsaw Blades

This blade is a precision-ground, hard-tooth bright carbon steel blade for food processing.

The razor-sharp hook teeth allow for maximum penetration while the unique, process-specific tooth set reduces waste for superior yield.

This sturdy blade can be used for a wide range of applications, including carcass-splitting and fresh or frozen meat cutting.

Suitable for cutting:

- Carcass splitting

- Fish

- Frozen fish or meat

- Meat

- Poultry

Benefits

- Superior yield, reducing product waste

- Cleaner cuts

- Food-grade oil coating for safe and immediate use

- Minimum downtime for longer production runs

What does the Blade Cut?

Standard order processing/manufacturing time is around 24-48hours

All orders placed before 4:00 pm Melbourne time go into production on the same day and dispatched the following afternoon.

Please Note: Bandsaw blades under the PREMIUM CATEGORY which include "TCT Timber, Carbide Grit and Diamond Coated Bandsaw Blades can take up to 4 weeks to 3 months to be shipped due to high demand and complexity of the production process.

For Enquires, please email [email protected] or phone 03 9005 7931.

- Delivery policy

We will arrange for the products to be delivered to the address for delivery indicated in your order. Each item will be subject to “Signed on Receipt”.

We will use reasonable endeavours to deliver products on the date for delivery set out in our order confirmation or, if no date is set out in our order confirmation, within 7 days of the date of our order confirmation. However, we cannot guarantee delivery by the relevant date.

We do however guarantee that unless there are exceptional circumstances all deliveries of products will be dispatched within 30 days of the later of receipt of payment and the date of our order confirmation

VIC 1 Day

NSW 2 Days

ACT 2 Days

TAS 3 Days

QLD 3 Days

NT 5 Days

SA 2 Days

WA 5 Days

5 out of 5 stars (based on 4 reviews)

Write a Review

Works Fine. Decent Quality

October 12, 2022

Found this blade in this shop and hoped that it would last longer. so far so good.

Well made. Cut well. Good buy.

May 3, 2022

Perfect fit.

Just what the doctor ordered. ????

Great value for your money

May 3, 2022

We use them everyday – High Recommended!!!

customer support staff was very helpful

May 3, 2022

The customer support staff was very helpful in finding out my machine’s details. The instruction on site were easy to follow and the blades arrived in a few days..

Meat & Fish Cutting Bandsaw Blades

Bandsaws are actually pretty effective in cutting completely frozen meat, even the one with bone in them. The only thing you need to change is the blade suitable for cutting meat.

Yes, just replace the blade with a food processing blade.

Clean the blades thoroughly using antibacterial soap or bleach and hot water to dislodge meat particles and germs that have clung to them. Sterilize by washing with hot water that is a temperature of 170 degrees

• Keep your machine properly aligned by making sure the guides are correctly positioned so the blade always tracks in the center of the guides. Look at the blade scrapers to make sure they are not hitting the blade teeth and dulling them.

• Be sure the saw blade tracks straight. Adjust the blade tension so it will not waver – too much tension and it will break. Adjust the blade back-up bearings so they only touch and support the back of the blade when the machine is running.

• Let the blade do the work so it will cut straight. If the blade is not worn out, it should cut the meat easily.

• Keep your saw guides, blade cleaners, fiber support blacks and back-up bearings in good condition. These are not expensive parts, but they affect the performance of the blade and keep it working longer.

• Keep the wheels clean and wheel scrapers in good condition. Make sure that the blade is aligned properly so it doesn’t ride on the wheel flanges.

• Always wear goggles and metal mesh safety gloves when operating a meat saw.

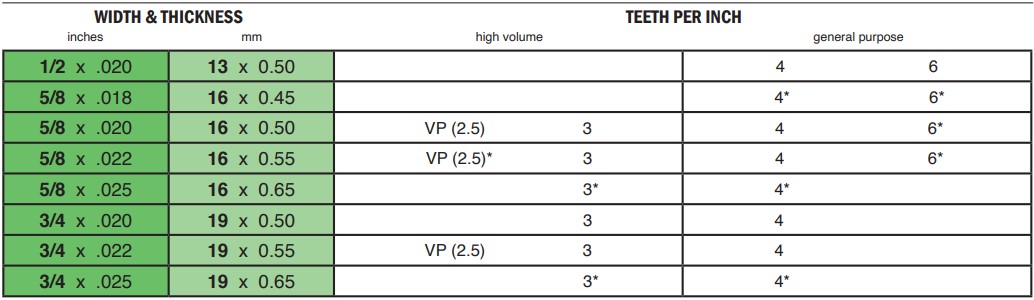

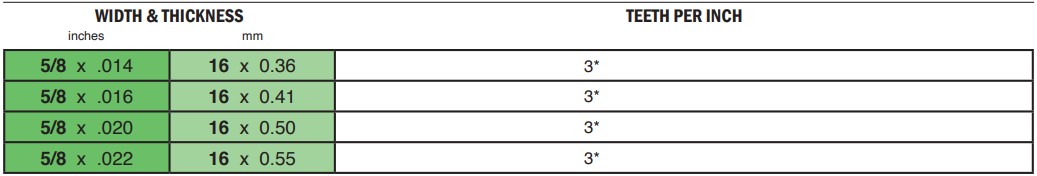

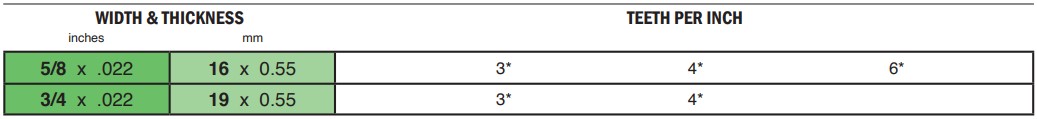

This usually depends on the blade speed of your bandsaw (contained in your operator’s manual) and is expressed in linear feet per minute of operation. Saws with a rating of 4000 or less lfpm usually perform better with a blade with 4 teeth per inch.

Those blades usually have an overall length of 106 inches or less. Newer high-speed saws with a rating in excess of 4000 lfpm usually work best with 3 tpi blades that are more than 106 inches in length.

Purchase Your Blade

5 Easy Steps to Build Your Own Sawblade

Welcome to the

Sawblade.com.au

Mobile App

3. Select the Length (Round up to the Closest Increment)(Round up to the Closest Increment)

2. Now Enter the Exact Length in (mm) (Made to your Order)

Length is not correct, changed to maximum allow length.

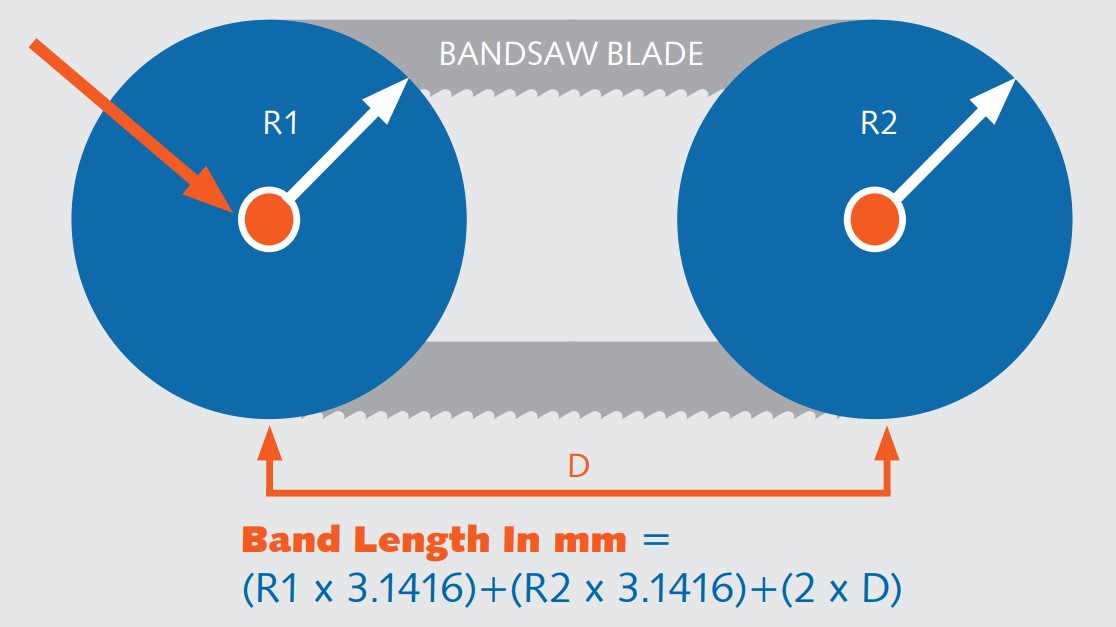

Adjust the wheels of the machine to their correct position (about the middle of the adjustment range)

- Refering to the diagram below, measure the distance between the centre point of each wheel in mm (measurement D).

- Now measure the radius of each wheel in mm (R1 and R2).

- Use this formula to calculate the band length

3. Select the TPI (Teeth Per Inch)

4. Great, Can I have your Name?

5. and your Contact Number?

Select Your Delivery Location

Delivery To:

Express Shipping Best for Small Orders

Order Details:

Bulk Pricing Best for Large Orders

Order Details:

Showing 1–12 of 60 results

-

$86.00

$86.00

Meat & Fish 7925mm x 13mm x 0.6

Add to cart -

$33.12

$33.12

Meat Bandsaw 1525mm x 13mm x 0.6 x 3

Add to cart -

$33.12

$33.12

Meat Bandsaw 1525mm x 13mm x 0.6 x 4

Add to cart -

$33.12

$33.12

Meat Bandsaw 1680mm x 13mm x 0.6 x 3

Add to cart -

$33.12

$33.12

Meat Bandsaw 1680mm x 13mm x 0.6 x 4

Add to cart -

$35.81

$35.81

Meat Bandsaw 1680mm x 16mm x 0.6 x 3

Add to cart -

$40.72

$40.72

Meat Bandsaw 1680mm x 19mm x 0.6 x 3

Add to cart -

$40.72

$40.72

Meat Bandsaw 1830mm x 19mm x 0.6 x 3

Add to cart -

$33.12

$33.12

Meat Bandsaw 1985mm x 13mm x 0.6 x 3

Add to cart -

$33.12

$33.12

Meat Bandsaw 1985mm x 13mm x 0.6 x 4

Add to cart -

$35.81

$35.81

Meat Bandsaw 1985mm x 16mm x 0.6 x 3

Add to cart -

$35.81

$35.81

Meat Bandsaw 1985mm x 16mm x 0.6 x 6

Add to cart

Shipping Australia Wide

Shipping Australia Wide