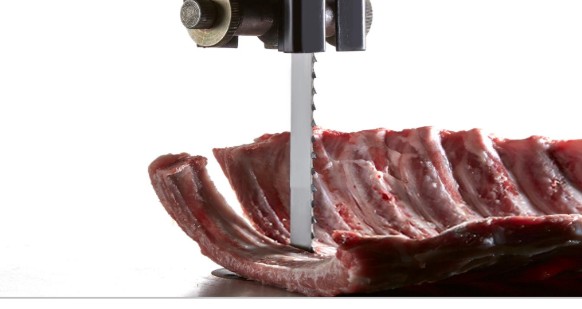

Bandsaw blades used for cutting meat, fish and poultry products are designed to be disinfected regularly. Designed to enable easy loading and unloading of the blade, you can easily clean the blade after every use. Unlike metal cutting bandsaw blades, blades used for cutting meat does not have the same precision around the blade guide. Meat cutting blades are specifically designed with razor-sharp hook teeth to allow maximum penetration, whilst the unique process-specific tooth set reduces waste for superior yield in food processing.

Razor Sharp Bandsaw Blades For Cutting Meat

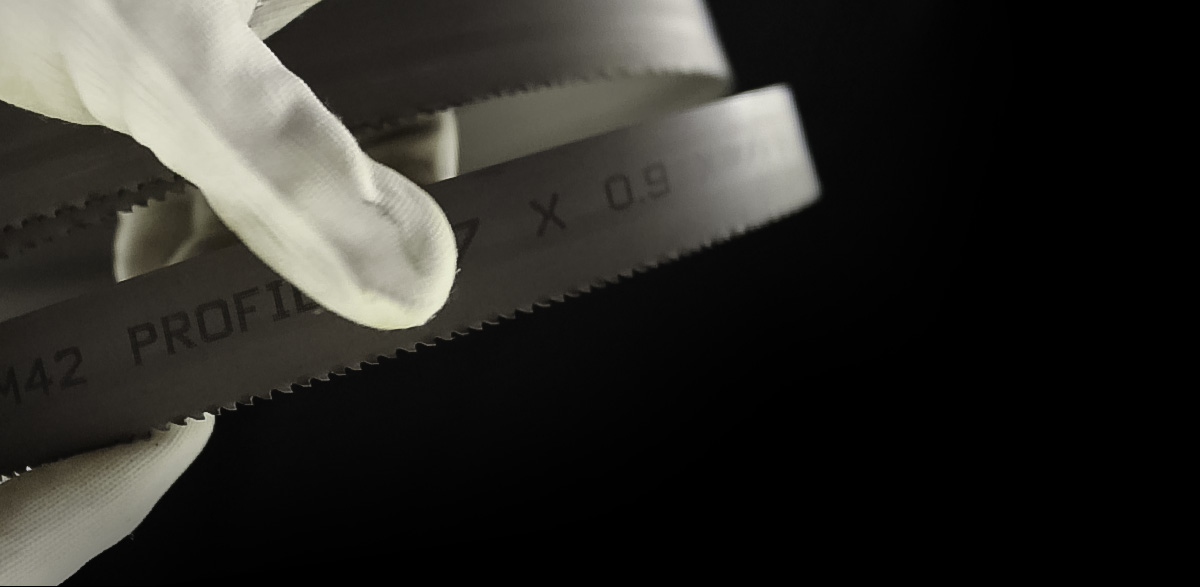

Any blade used for cutting food products should adhere to the strict standards and regulations for handling food. In addition, all blades should be of the highest quality to guarantee a quality end product. Blades at Sawblade.com.au are manufactured in Australia with a primary focus on meeting food safety guidelines. They are coated with food-grade mineral oil and are ready for immediate use.

The sharpness and durability of our blades are a testament to our benchmark production plan which produces the best quality blades for cutting meat and food products. Our blades not only produce visually superior looking end products but also minimises replacement costs and downtime.

Superior and Reliable Cut Every Time

All blades manufactured at our facilities yield superior cutting performance and suit a huge range of cutting applications. Our expertise and speciality in the welding process ensure that we have built a reputation for delivering bandsaw blades with the strongest joints.

Delivering All Across Australia

Based in Oakleigh, VIC, Sawblade.com.au generates a manufacturing turnaround time of only one day after receiving an order from the customer. Orders are shipped the next day with your blades safely packaged to reach you in top condition. Our estimated delivery time for orders within VIC is an astonishing 1 day.

We take 2 days for orders from NSW, ACT and SA and 3 days for TAS and QLD. Sawblade.com.au is one of the quickest and efficient bandsaw blade dealers, manufacturing and delivering blades all across Australia.

Get in touch with us and we would be delighted to guide you through the process of selecting the best blades for your application.

Shipping Australia Wide

Shipping Australia Wide

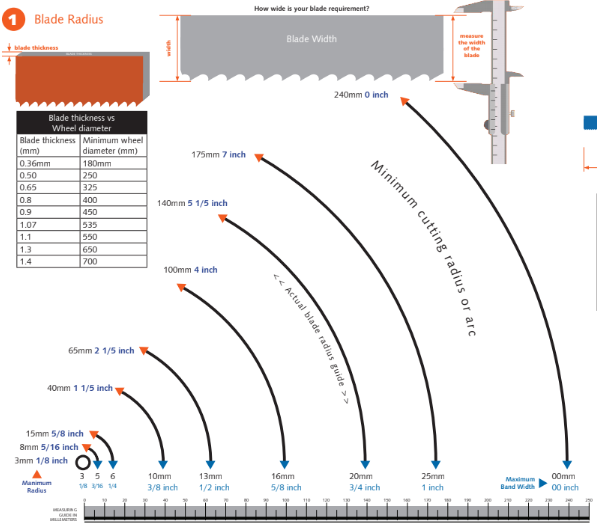

A blade that is being used for cutting bowls will not be ideal for cutting curves. Consequently, cutting curves disturbs the teeth of the blade rendering it incapable of performing straight cuts. So the best advice we can give you is to keep a separate blade for every application. Also, blade dimensions may vary depending on the actual thickness of the wood.

A blade that is being used for cutting bowls will not be ideal for cutting curves. Consequently, cutting curves disturbs the teeth of the blade rendering it incapable of performing straight cuts. So the best advice we can give you is to keep a separate blade for every application. Also, blade dimensions may vary depending on the actual thickness of the wood. Designed To Perform Perfect Cuts

Designed To Perform Perfect Cuts

Another rule of thumb to follow is that at least 3-6 teeth should be involved in the cut at all times. This leads to accuracy and stability and applies to both metal and wood. If the correct TPI is not chosen, the blade life will be dramatically shortened.

Another rule of thumb to follow is that at least 3-6 teeth should be involved in the cut at all times. This leads to accuracy and stability and applies to both metal and wood. If the correct TPI is not chosen, the blade life will be dramatically shortened.