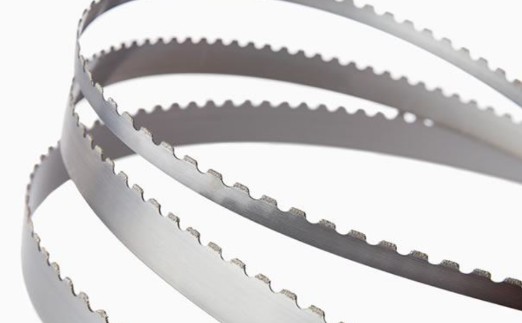

Using bandsaw blades to cut glass makes it easier to cut heavily textured, fused, or thick glass. However, not all bandsaw blades are suitable for cutting glass. Bandsaw blades used for cutting glass are coated with a high quantity of multi-faceted diamond grains. The facets of the diamond grains create an extreme number of cutting edges, giving a smooth surface finish.

One Blade For Various Glass Cutting Methods

The most prevalent method of cutting glass using a bandsaw blade is advantageous because you can control the feed rate. Blade speed can also be moderated to stop the blade from heating up. Lesser blade speed means the diamond grains have more time to cool off before it comes back for the next cut.

Using a coolant can massively increase productivity and also increase blade longevity. The diamond grains are attached to the blade using a bond. When the diamond is pressed against the glass to be cut and is moved very fast, it generates heat and makes the bonding material hot. The heating of the bonding material makes it soft and increases the possibility of the diamond grains falling off. Using a coolant takes heat away from the diamond and protects them from falling.

Diamond Cutting Bandsaw Blades Designed To Perfection

The Diamond bandsaw blades manufactured at Sawblade.com.au is coated with a high quantity of multi-faceted diamond grains, galvanised on a highly flexible backing strip. The facets of the grains create an extreme number of cutting edges, giving a smooth surface finish.

We only use highest-grade German steel to manufacture our bandsaw blades. Band welded in Australia and put through rigorous testing, every blade is guaranteed to perform to perfection. We manufacture blades suitable for cutting glass-fired ceramics, stone, silicon, marble, glass, porcelain, and fibreglass.

Delivering Full Range Of Blades All Across Australia

We have a wide range of bandsaw blades available for your selection. Ranging in width from 6mm to over 30mm, diamond cutting bandsaw blades are also available with TPI(teeth per inch) up to 18tpi.

We take 2 days for orders from NSW, ACT and SA and 3 days for TAS and QLD. Sawblade.com.au is one of the quickest and efficient bandsaw blade dealers, manufacturing and delivering blades all across Australia.

Get in touch with us and we would be delighted to assist you in finding the best blade suited for your requirements.

Shipping Australia Wide

Shipping Australia Wide