Before starting your metal cutting operation, careful selection of the correct circular saw blade is the most critical step. Just like wood cutting, metal cutting also requires a different type of blade depending on the metal you are going to cut. The following sections will inform and educate you on the subject of how to select the correct circular saw blade for cutting metals.

Metal Cutting Process Using Circular Saw Blades

Metal cutting process using circular saw blades involves a series of steps needed to be done carefully to achieve the maximum output. Follow the instructions below, and you will make the step up from barely meeting your goals to standing out from the rest of the pack.

Right Blade Selection

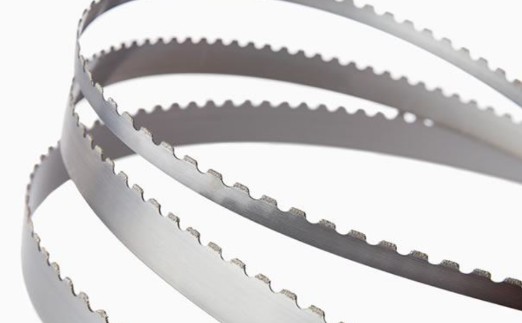

The metal cutting bandsaw blade must be selected depending on the thickness and toughness of the metal you are going to cut. You must vary the blades of diameter for cutting different metals to keep each blade sharp and prolong its usability.

Insert And Adjust The Blade

After inserting the blade in the circular saw, properly tighten all the screws and clamps. This keeps the blade in place and makes sure that the blade is held tightly against the saw.

Using the adjustment slide on the saw machine, adjust the blade by moving it up or down. The depth of the blade in the saw machine must be adjusted so that blade is held against the metal with not more than 1/4th of an inch of the metal touching the blade.

Full Range Of Circular Saw Blades Designed To Outperform The Rest

At sawblade.com.au, we produce blades for every metal cutting operation, which is a testament to our benchmark production plan. We produce blades that work equally well at both fast and slow RPMs. The specifically designed blades produce minimal vibrations and spins.

Our metal cutting circular blades provide uniform cutting for a long period, saving you heaps of money in the process.

Delivering All Across Australia

Based in Hamilton, VIC, Sawblade.com.au generates a manufacturing turnaround time of only one day after receiving an order from the customer. Orders are shipped the next day with your blades safely packaged to reach you in top condition. Our estimated delivery time for orders within VIC is an astonishing 1 day.

We take 2 days for orders from NSW, ACT and SA and 3 days for TAS and QLD. Sawblade.com.au is one of the quickest, and most efficient bandsaw blade dealers, manufacturing and delivering blades all across Australia.

Get in touch with us and we will guide you through the process of selecting a carbide impregnated bandsaw blade suited to your requirements.

Shipping Australia Wide

Shipping Australia Wide