Diamond Bandsaw Blade

Diamond Bandsaw Blade

The Premium Quality Diamond Coated Bandsaw Blade is created to deliver sheer cutting excellence by our uncompromising metallurgical properties and manufacturing techniques. It is capable of machining almost all materials where other cutting materials fail due to their physical properties.

Your first choice for cutting extremely brittle and abrasive materials such as Glass, Graphite, Silicon, Hard Coal, Ceramics, Concrete Materials, CFRP, Sintered Materials, Perforated Bricks, and Clinker as well as to cut mineral building materials such as Calcareous or Natural Stone.

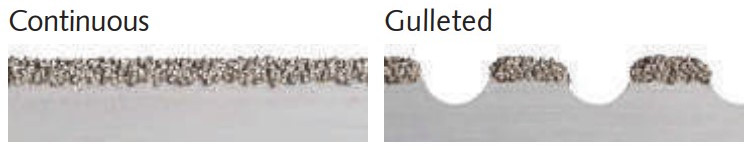

Diamond Bandsaw Blade Gulleted is made in a Premium Quality Diamond Coated Bandsaw Blade is created to deliver sheer cutting excellence by our uncompromising metallurgical properties and manufacturing techniques. It is capable of machining almost all materials where other cutting materials fail due to their physical properties.

Your first choice for cutting extremely brittle and abrasive materials such as Glass, Graphite, Silicon, Hard Coal, Ceramics, Concrete Materials, CFRP, Sintered Materials, Perforated Bricks, and Clinker as well as to cut mineral building materials such as Calcareous or Natural Stone.

Diamond Bandsaw Blade Continuous is a premium quality bandsaw blade designed to deliver sheer cutting excellence through uncompromising metallurgical properties and manufacturing techniques. It can machine almost any material that other cutting materials cannot due to their physical properties.

Advantages Of Using Diamond Bandsaw Blades

- Significantly faster cutting rates

- Increased blade life

- Exceptional performance

- Continuous or gulleted edge

- Increased blade life

- Reversible blade

Suitable For Cutting

Diamond Bandsaw Blade

0 out of 5 stars (based on 0 reviews)

The Premium Quality Diamond Bandsaw Blade is created to deliver sheer cutting excellence by our uncompromising metallurgical properties and manufacturing techniques. It is capable of machining almost all materials where other cutting materials fail due to their physical properties.

-

Free Shipping

over $350 Australia wide

Free Shipping

over $350 Australia wide

-

Manufactured

Manufactured

in Australia Purchase Direct -

100% Safety

Only Secure Payments

100% Safety

Only Secure Payments

-

Australia Wide Shipping Only

LIVE: Orders Placed Today

Australia Wide Shipping Only

LIVE: Orders Placed Today

Talk to our Blade Expert

Get in Touch!

Request a Blade Specialist to give you a Call

Technical Specifications

| Item | Diamond Bandsaw Blade Continuous/Gulleted |

| Materials Cut | Carbon Fibre Reinforced Plastic(CRP), Concrete, Glass, Industrial Ceramics, Silicon Materials |

| Cutting Edge Style | Variable |

| For Use With Saw Type | Bandsaws |

Diamond Bandsaw Blade

The Premium Quality Diamond Coated Bandsaw Blade is created to deliver sheer cutting excellence by our uncompromising metallurgical properties and manufacturing techniques. It is capable of machining almost all materials where other cutting materials fail due to their physical properties.

Your first choice for cutting extremely brittle and abrasive materials such as Glass, Graphite, Silicon, Hard Coal, Ceramics, Concrete Materials, CFRP, Sintered Materials, Perforated Bricks, and Clinker as well as to cut mineral building materials such as Calcareous or Natural Stone.

Diamond Bandsaw Blade Gulleted is made in a Premium Quality Diamond Coated Bandsaw Blade is created to deliver sheer cutting excellence by our uncompromising metallurgical properties and manufacturing techniques. It is capable of machining almost all materials where other cutting materials fail due to their physical properties.

Your first choice for cutting extremely brittle and abrasive materials such as Glass, Graphite, Silicon, Hard Coal, Ceramics, Concrete Materials, CFRP, Sintered Materials, Perforated Bricks, and Clinker as well as to cut mineral building materials such as Calcareous or Natural Stone.

Diamond Bandsaw Blade Continuous is a premium quality bandsaw blade designed to deliver sheer cutting excellence through uncompromising metallurgical properties and manufacturing techniques. It can machine almost any material that other cutting materials cannot due to their physical properties.

Advantages Of Using Diamond Bandsaw Blades

- Significantly faster cutting rates

- Increased blade life

- Exceptional performance

- Continuous or gulleted edge

- Increased blade life

- Reversible blade

Suitable For Cutting

Standard order processing/manufacturing time is around 24-48hours

All orders placed before 4:00 pm Melbourne time go into production on the same day and dispatched the following afternoon.

Please Note: Bandsaw blades under the PREMIUM CATEGORY which include "TCT Timber, Carbide Grit and Diamond Coated Bandsaw Blades can take up to 4 weeks to 3 months to be shipped due to high demand and complexity of the production process.

For Enquires, please email [email protected] or phone 03 9005 7931.

- Delivery policy

We will arrange for the products to be delivered to the address for delivery indicated in your order. Each item will be subject to “Signed on Receipt”.

We will use reasonable endeavours to deliver products on the date for delivery set out in our order confirmation or, if no date is set out in our order confirmation, within 7 days of the date of our order confirmation. However, we cannot guarantee delivery by the relevant date.

We do however guarantee that unless there are exceptional circumstances all deliveries of products will be dispatched within 30 days of the later of receipt of payment and the date of our order confirmation

VIC 1 Day

NSW 2 Days

ACT 2 Days

TAS 3 Days

QLD 3 Days

NT 5 Days

SA 2 Days

WA 5 Days

0 out of 5 stars (based on 0 reviews)

Write a Review

There are no reviews yet. Be the first one to write one.

Diamond Bandsaw Blade Gulleted

Diamond Blades for cutting Engineered Stone such as Quartz

Quartz and engineered stones are both very hard materials to cut, because of quartz density it can only be cut with a diamond blade suitable for hard material.

Yes, certain diamond blades can cut through metal, but this will depend entirely on the blades application. Most diamond blades are used to cut through concrete, brick, tile, and asphalt. Usually, each blade is specialized to cut a certain material or hardness of materials.

Diamond blades aren’t the best choice for cutting wood. As stated earlier, these saws are manufactured to handle the toughest materials, and wood isn’t one of those. Wood, especially boards, have soft fibers which can easily be damaged when the cut is not done correctly.

Well, the answer is no. Diamond blades only have synthetic diamond particles on its diamond segments. These diamond segments, or the cutting edge of the blade, are made from diamond crystals which were heated with powder metal and then pressed into a molding, forming it.

If you want to know how to tell if a diamond saw blade is dull, you need to keep an eye on it and check these symptoms:

Unusual vibrations when the saw is turned on.

1. Slow cutting speed when working on an easy material.

2. Obvious signs of warping or damage.

3. Unusual thumping noises when cutting.

Diamond blades are composed of diamond impregnated segments attached to the steel core. They are used to cut cured concrete, green concrete, asphalt, brick, block, marble, granite, ceramic tile, or just about anything with an aggregate base.

Gulleted blades typically have medium to hard bonds for a range of wet and dry cutting applications. While these diamond saw blades can offer a relatively smooth cut with a fast cutting speed, chipping may still occur. They are durable and have a long blade life compared to other blades.

They are ideal for cutting marble and granite slabs, concrete, asphalt, brick, block, and other building materials.

The spaces of air that separate the diamond segments are called gullets or slots. The slots are there to improve air flow, cutting materials dust, dissipate heat, and remove slurry from the cut, helping to maintain the saw blade’s cutting performance. The size and shape of the gullets vary from blade to blade and will depend on the type of material the blade designed to cut.

Purchase Your Blade

5 Easy Steps to Build Your Own Sawblade

Welcome to the

Sawblade.com.au

Mobile App

3. Select the Length (Round up to the Closest Increment)(Round up to the Closest Increment)

2. Now Enter the Exact Length in (mm) (Made to your Order)

Length is not correct, changed to maximum allow length.

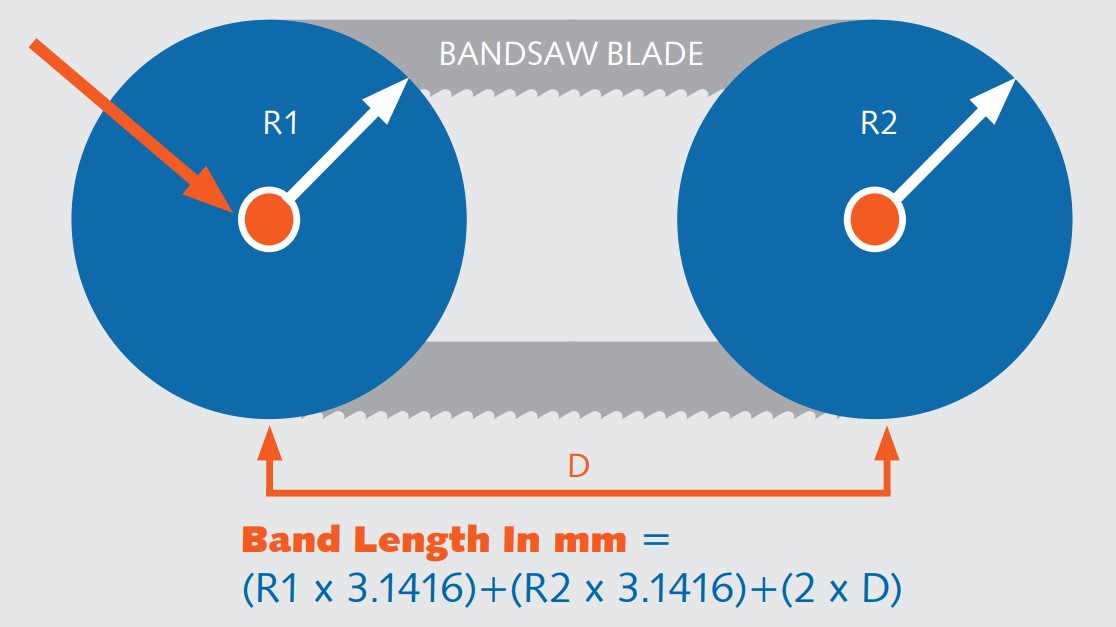

Adjust the wheels of the machine to their correct position (about the middle of the adjustment range)

- Refering to the diagram below, measure the distance between the centre point of each wheel in mm (measurement D).

- Now measure the radius of each wheel in mm (R1 and R2).

- Use this formula to calculate the band length

3. Select the Edge Type

4. Great, Can I have your Name?

5. and your Contact Number?

6. Enter Quantity

Please Click Step 1 to Reload Blade Engine. Step 1

Order Your Blade

Order Details:

Showing the single result

Download the Bandsaw Blade Brochure

Download The Company Brochure as a PDF

- Detailed Overview on What the Blade Can Cut

- Technical Specifications on Each Blade

- Material and Profile Guide Map per each Blade

Shipping Australia Wide

Shipping Australia Wide