Metal Cutting Bandsaw Blades

3 Things to Consider When Buying Metal Cutting Bandsaw Blades

There are three things you need to consider when purchasing metal cutting bandsaw blades.

-

The Material you are cutting; Metal cutting blades can cut different kinds of materials. It is important to determine the size and thickness of the material and that is paired correctly with the appropriate blade. -

Type of Machine. The type of machine is a relevant thing to consider when purchasing metal blades as that may limit that size blade you can use. -

Bandsaw Blades Quality. Indeed, you can avoid further problems with high-quality blades. If your bandsaw machine is set up correctly and you are using the correct amount of lubrication. Ask customer support what the benchmark (quality of life) should be for a given blade.

Get Started with Metal Bandsaw Blades

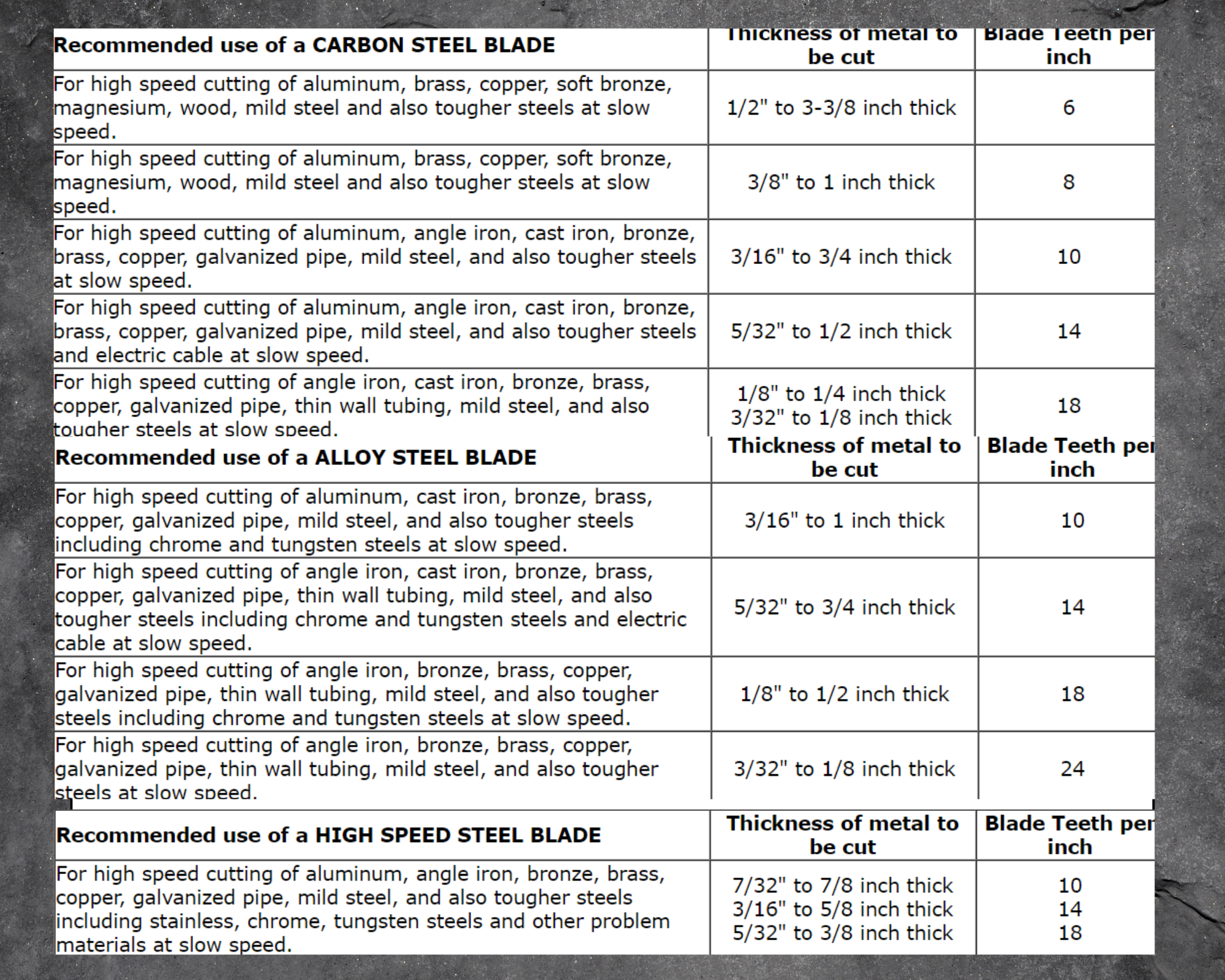

To help you get started here is a chart that details the thickness of the material in relation to what you are cutting.

The (Teeth Per inch) is the number you must request when we manufacture the blade for you.

Request a quote, or use our special Build Your Blade Website Form to Get Started.

You can also reach the company directly on 03 9005 7931.

If you want some troubleshooting tips, click this link How to Reduce Bandsaw Vibration.

Shipping Australia Wide

Shipping Australia Wide