There are different types of circular saw blades available in the market. Any saw machine is only as good as the blade you put in them. Even using the appropriate speed and feed rate will not help if you are using the wrong blade for the purpose.

Circular saw blades are easy to handle and perfect for making quick, accurate cuts. In this post, we are going to look at different types of circular saw blades and the types of work you can do with them. Those include the framing blade, metal cutting circular saw blade, ripping blade, finishing blade, and masonry blade. Of course, you’ll also want to be sure to get the right size circular saw blade.

Circular Saw Blades Types And Uses

There are several types of circular saw blades available in the market. Each blade has a different design and feature to cut through a certain type of material. Because each blade has a specific purpose, you must choose a blade designed to do what your project demands.

A blade designed for rip cuts should not be used to make crosscuts, for example. Not only will using the wrong blade result in an unsatisfactory cut, but it can even be dangerous. Using the wrong type of blade can cause it to snap while in use, which can be a safety hazard. Experts at Sawblade.com.au have put together a guide to teach you about the different types of circular saw blades and their application.

Crosscutting Blades

These types of blades are best in cutting across the grains of wooden materials. They have more teeth and a gullet which is shallow compared to other blades, hence suitable for the task. They produce smoother and cleaner results, and they cut at a slow rate.

Plywood Blade

Because the plywood flakes and chips are not hard, the plywood blade has more teeth than the crosscutting blade. They usually have more than 40 teeth. The blade is designed to use on smooth materials hence helping to minimise the splintering of wood when cutting.

General-Purpose Blades

Also known as combination blades, they fall between crosscutting and ripping blades. These are only the best choice if one needs a single blade for a variety of tasks. But when one needs a blade for a specific task, it’s advisable to get a particular blade designed for that particular task.

Ripping Blades

These blades are not made to cut across a wood grain but along. They are characterised by a few teeth, not more than 24. They have deep gullets and are suitable for making rough cuts faster.

Finishing Blades

These blades used to make cuts that are clean and exact on wood. They make cuts on a wood that will most likely be noticeable after the intended task is complete. They have more teeth for making smooth cuts. Because of the extra teeth, they don’t cause any damage to the wood.

Masonry Blades

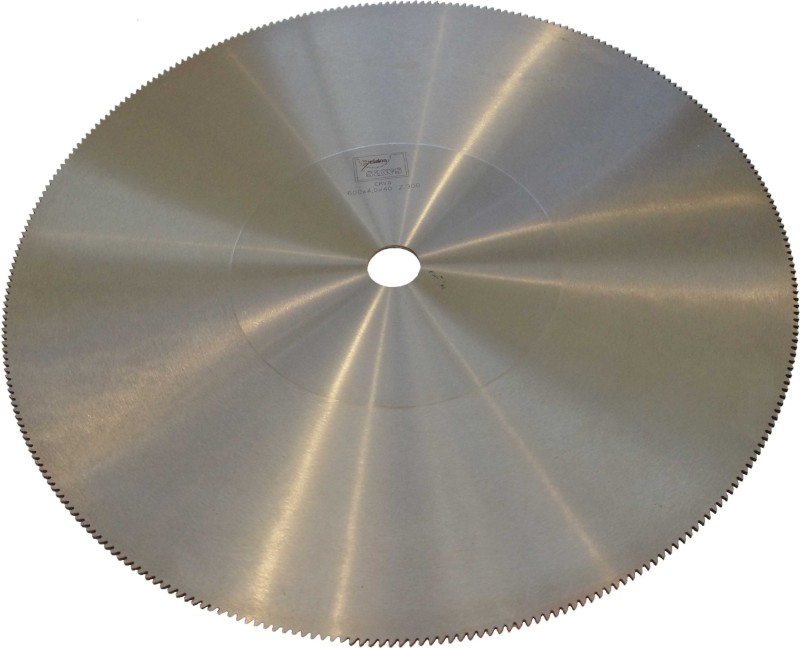

These blades are different from the kinds of blades that are used to cut wood. They do not have teeth on them, making them different from wood cutting blades. These blades are made up of different materials from the woodcutting blades. Masonry blades are the only type of blades that only works when cutting masonry or any task related to it.

Shipping Australia Wide

Shipping Australia Wide