In this article, we at Sawblade.com.au, have put together a series of instructions and recommendations for band speed and feed rates to meet the diverse requirements of a bi-metal sawing application. A singular blade cannot cut all kinds of material, you need a separate blade for different applications. Even possessing a separate blade is not enough, you need to make sure to apply the correct feed rate and band speed to ensure the longevity and safety of the blade and the cutting material.

Recommended Band Speed and Feed Rates

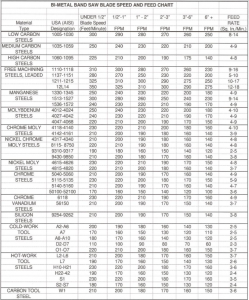

Below is the industry-accepted feed rate and band speed standards. Note that the rates and speeds differ for a different type of bandsaw blade.

Many factors affect band sawing efficiency: tooth design, band speed, feed rates, vise loading, lubrication, the condition of the machine, and the material you are cutting. Let’s talk about the most important factors in a little more detail.

Many factors affect band sawing efficiency: tooth design, band speed, feed rates, vise loading, lubrication, the condition of the machine, and the material you are cutting. Let’s talk about the most important factors in a little more detail.

Feed Rate

Feed refers to the depth of penetration of the tooth into the material being cut. For cost-effective cutting, you want to remove as much material as possible as quickly as possible by using as high a feed rate as the machine can handle. However, the feed will be limited by the machinability of the material being cut and blade life expectancy.

A deeper feed results in a lower shear plane angle. Cutting may be faster, but blade life will be reduced dramatically. Light feed will increase the shear plane angle but increase the cost per cut.

Band Speed

Band speed refers to the rate at which the blade cuts across the face of the material being worked. A faster band speed achieves a higher, more desirable shear plane angle and hence more efficient cutting. This is usually stated as FPM (feet per minute) or MPM (meters per minute).

Band speed is restricted, however, by the machinability of the material and how much heat is produced by the cutting action. Too high a band speed or very hard metals produce excessive heat, resulting in reduced blade life.

How do you know if you are using the right band speed? Look at the chips; check their shape and colour. The goal is to achieve chips that are thin, tightly curled, and warm to the touch. If the chips have changed from silver to golden brown, you are forcing the cut and generating too much heat. Blue chips indicate extreme heat which will shorten blade life.

Shipping Australia Wide

Shipping Australia Wide